How does the silver-white pearlescent pigment production process ensure batch-to-batch consistency?

The silver-white pearlescent pigment production process ensures batch-to-batch consistency through multi-faceted control and management, including the following key aspects:

Raw material supply chain management: Ensure the procurement of high-quality raw materials from stable and reliable suppliers, such as mica, titanium dioxide and other basic materials. The quality of these raw materials directly affects the performance and consistency of the final product.

Raw material acceptance standards: Establish strict raw material acceptance standards and processes, and conduct comprehensive testing and evaluation of each batch of incoming raw materials to ensure that they meet the requirements of product design.

Formula design and optimization: Engineers formulate precise production formulas based on product design requirements and market feedback, including the proportion of each raw material, addition order and process parameters. These formulas are systematically verified and optimized to ensure that each production can meet consistent quality standards.

Process parameter control: Strictly control process parameters such as stirring time, temperature, pressure and other key factors during the production process. The precise control of these parameters can reduce variability in production and ensure that each batch of products has consistent physical and chemical properties.

Batch testing: Conduct comprehensive quality testing on each batch of silver-white pearlescent pigments produced. This includes physical property testing (such as particle size distribution, gloss), chemical property testing (such as chemical stability, solubility) and color difference control.

Color difference control: Use high-precision color difference instruments to measure the color difference of each batch of pigments to ensure that the color difference between it and the standard sample is within the allowable range. This is a key step to ensure color consistency, especially for silver-white pearlescent pigments, where even a small color difference may significantly affect the appearance of the final product.

Production environment control: Maintain stable production environment conditions, including temperature and humidity control, cleanliness management, etc. These control measures help reduce the impact of external factors on the production process and ensure the consistency of product quality.

Advanced production equipment: The use of advanced and sophisticated production equipment and technology can improve production efficiency and product quality stability. For example, automated mixing systems, sophisticated dispersing equipment, etc. help ensure uniform dispersion of pigments and improve production consistency.

Customer feedback and problem solving: Collect customer feedback regularly to identify and solve problems that may affect product consistency in a timely manner. Establish effective customer communication channels and feedback mechanisms to promote the connection between production and market demand.

How to ensure consistent color difference control between batches of silver-white pearlescent pigments?

Color difference control of silver-white pearlescent pigments is one of the key steps to ensure consistency between different batches. Color difference refers to the degree of color difference between different samples of the same color. For silver-white pearlescent pigments, even small color differences may significantly affect the appearance and quality of the final product. The following are color difference control strategies to ensure batch-to-batch consistency:

Use color difference instruments: Manufacturers use high-precision color difference instruments to conduct accurate color difference measurements for each batch of silver-white pearlescent pigments. A colorimeter can quantitatively measure the color difference between a color sample and a standard sample, usually expressed as ΔE value (Delta E).

Set color difference standards: Establish strict color difference standards to determine the allowable color difference range for each batch of pigments. This can be formulated based on market demand, customer requirements or product specifications, usually requiring the ΔE value to be within a certain range.

Development of Standard Samples: Develop and maintain a set of standard samples that represent the desired colors and effects. Standard samples are usually certified and verified and represent the ideal appearance of the product.

Comparison of samples from each batch to standard samples: Each time a new batch of pigments is produced, samples are taken for direct comparison with standard samples. This can be done with a colorimetric instrument to ensure that the color of the new batch of pigments is consistent with the standard sample, or within a reasonable color difference range.

Production process control: Ensure that the process parameters of each key step during the production process are strictly controlled, such as raw material mixing, reaction time, temperature, pressure, etc. The stability of these parameters is crucial for color difference control of pigments.

Environmental condition control: Maintain stable production environment conditions, including temperature and humidity control, cleanliness management, etc. The stability of environmental conditions can reduce the impact of external factors on pigment color differences.

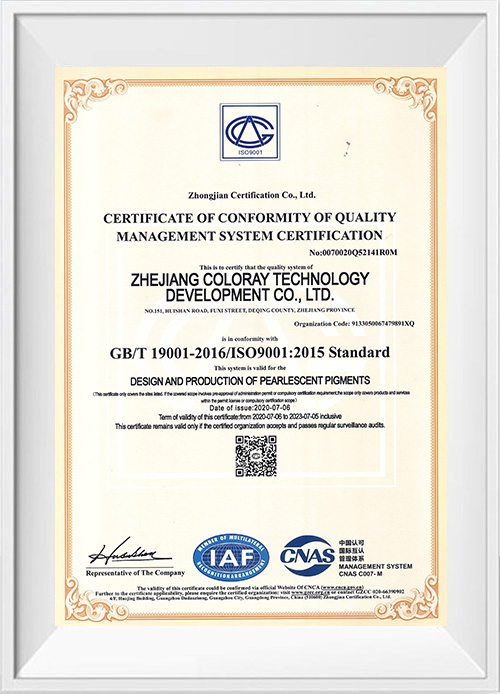

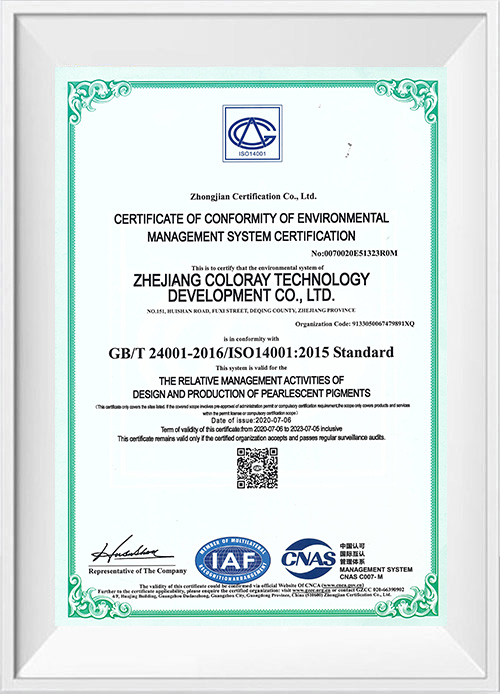

Implement quality management system: Quality management systems such as ISO 9001 ensure that all color difference control and quality control measures are systematically implemented and continuously improved.

Regular review and improvement: The color difference control strategy is regularly reviewed and improved, and adjustments are made based on customer feedback, market trends, technological progress and other factors to continuously improve the efficiency and accuracy of color difference control.