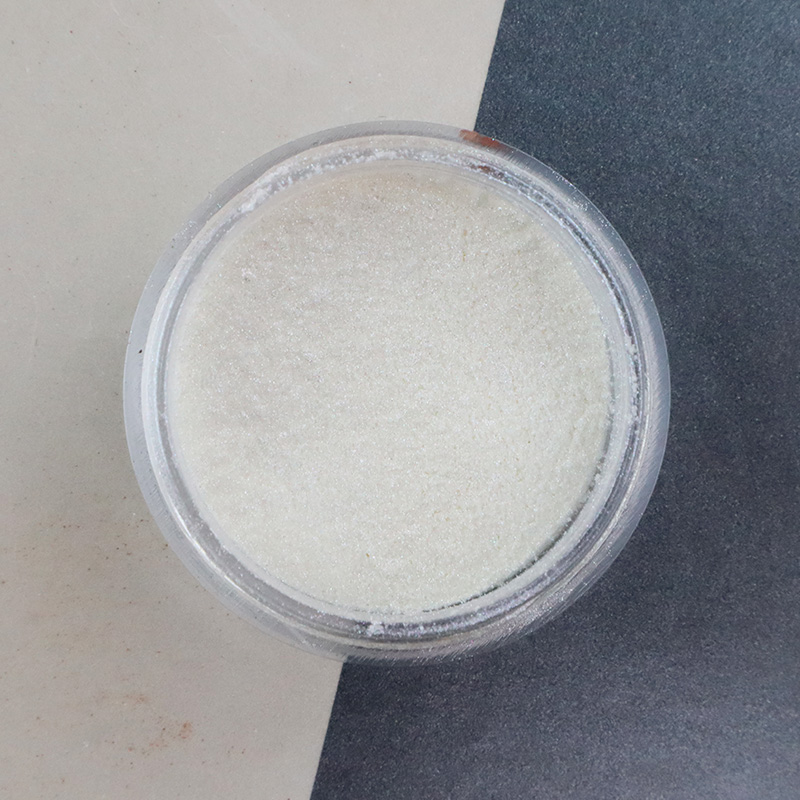

Titanium Dioxide Free Snow Velvet Silver-white Pearlescent Pigment Industry knowledge

What should I do with titanium dioxide-free snow velvet silver-white pearlescent pigment that has expired?

Titanium dioxide-free snow velvet silver-white pearlescent pigments that have expired should be properly disposed of based on their characteristics and potential environmental impact. Here are the steps and considerations for handling expired paint:

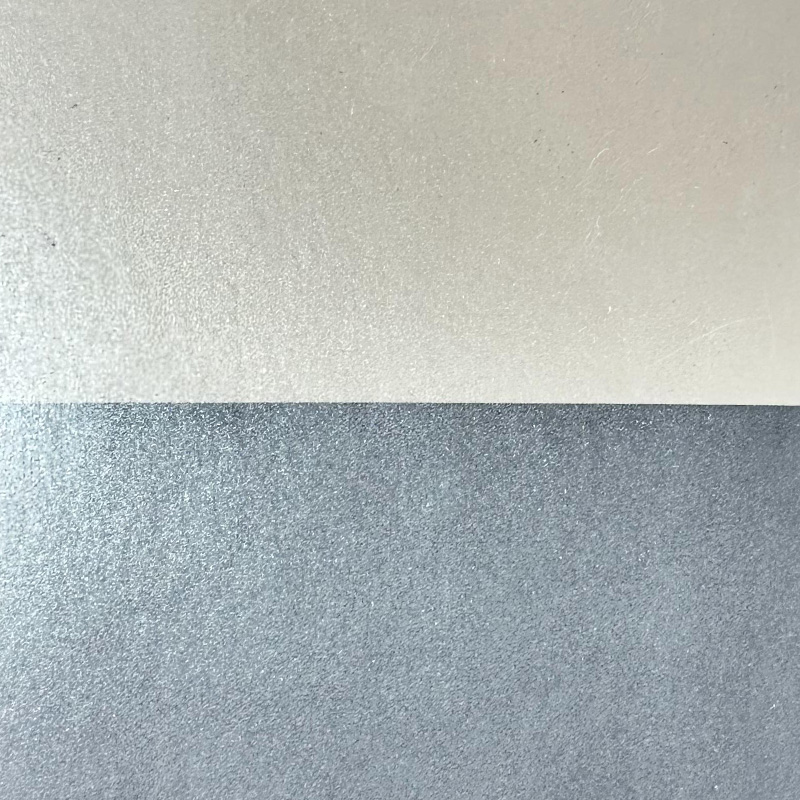

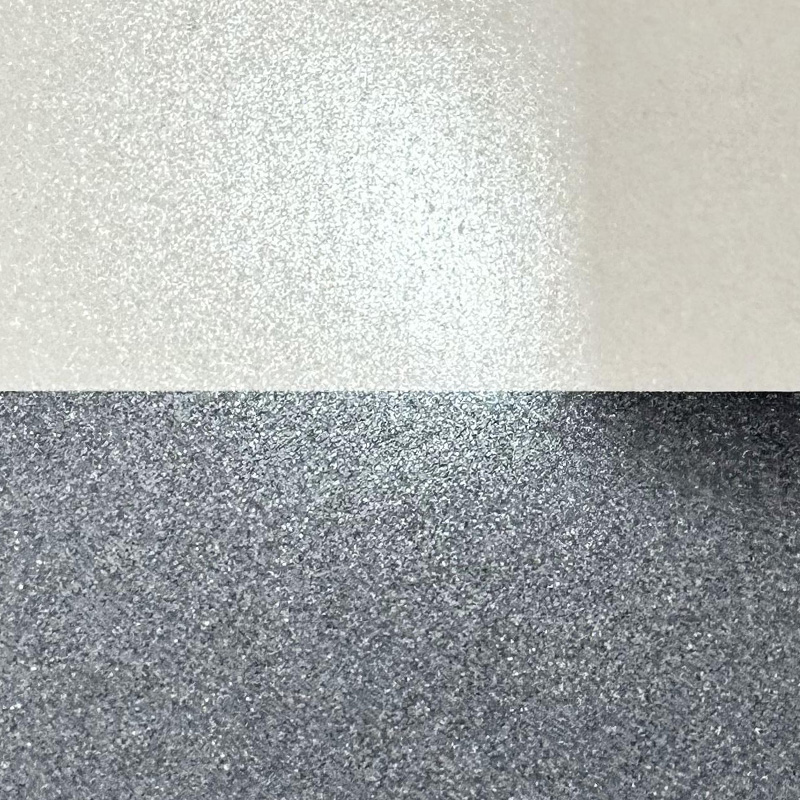

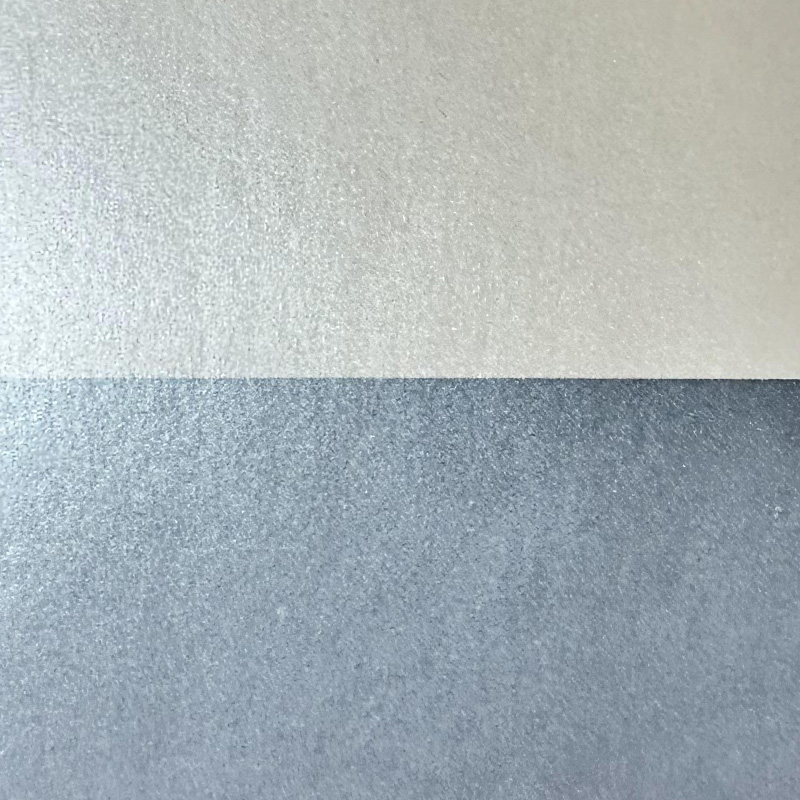

Check physical properties: Check the appearance, color, gloss and particle state of the pigment. If the paint does not show significant deterioration or odor, further testing may be considered.

Conduct performance testing: Conduct small-scale performance testing on pigments to evaluate how they will perform in real-world applications. If performance still meets requirements, consider continued use in non-critical applications.

Recyclable: If the performance of the pigment is not significantly degraded after evaluation, it can be stored in categories and marked as "restricted" pigments, with priority being used in applications that do not require high performance.

Non-recyclable: If the pigment has obviously deteriorated or its performance has seriously degraded, it is recommended not to use it anymore and needs to be properly disposed of.

Dispose in compliance with local regulations: Know and follow local regulations and guidelines for chemical waste disposal. Different regions may have different requirements for chemical waste disposal.

Contact a professional disposal agency: If you are not sure how to dispose of expired paint, it is recommended to contact a professional waste disposal agency or environmental protection department for guidance and assistance.

Avoid environmental pollution: Ensure that the treatment process does not pollute the environment and avoid direct dumping or random disposal of paint.

Record the processing process: record the processing process of expired pigments in detail, including quantity, processing date, processing method and other information for future inquiry and tracking.

Report to relevant departments: As necessary, report the handling of expired pigments to the company's internal environmental protection department or external regulatory agencies to ensure compliance with regulatory requirements.

Reasonable inventory management: Strengthen inventory management to avoid excessive backlog of pigments, adopt the first-in-first-out principle, and give priority to pigments that have been stored for a longer period of time.

Regularly check inventory: Regularly check the status and shelf life of inventory pigments, and promptly handle expiring pigments to reduce waste and environmental risks.

Optimize procurement and usage plans: Adjust procurement and usage plans based on actual needs to avoid excessive procurement and long-term storage.

How to choose the storage location of Titanium Dioxide Free Snow Velvet Silver-white Pearlescent Pigment?

When choosing the storage location of Titanium Dioxide Free Snow Velvet Silver-white Pearlescent Pigment, you need to consider a variety of factors to ensure that the quality and performance of the pigment will not be affected. Here are specific suggestions for choosing a storage location:

Constant temperature: Choose a storage location with a relatively constant temperature to avoid temperature fluctuations. The ideal storage temperature is 15°C to 25°C.

Away from heat sources: Avoid storing pigments near heat sources (such as heaters, boilers, direct sunlight, etc.) to prevent excessive temperatures.

Low humidity environment: The storage environment should be kept dry and the humidity should be less than 60%. Excessive humidity may cause the pigment to absorb moisture, agglomerate or deteriorate.

Moisture-proof equipment: Install moisture-proof equipment or use a dehumidifier in the storage area to ensure that the ambient humidity remains within an appropriate range.

Storage away from light: Choose a storage location away from light and avoid direct sunlight. Ultraviolet rays and strong light may affect the optical properties and chemical stability of the pigment.

Light-blocking measures: If light exposure cannot be avoided, use blackout curtains or opaque covers to block it.

Good ventilation: The storage location should be well ventilated to maintain air circulation and prevent the accumulation of humid air.

Prevent dust: At the same time, pay attention to prevent dust and impurities from entering the storage area, and use air filtration devices.

Flat ground: Choose a storage location with a flat ground to prevent the pigment container from tilting, falling or mechanical damage.

Anti-vibration: Avoid storing pigments in places that are prone to vibration or impact, such as near machinery and equipment or in areas with heavy traffic.

Stay away from fire sources: The pigment storage location should be away from fire sources and flammable and explosive items. The storage area should be equipped with appropriate fire prevention equipment, such as fire extinguishers.

Fire escape: Ensure that the storage area has clear fire escapes and emergency exits to facilitate rapid evacuation in an emergency.

Clear markings: Mark clear safety markings on the storage area and containers, including the pigment name, batch number, storage precautions, etc.

Safety management: Strictly manage the entry and exit of the storage area to ensure that only authorized personnel can enter and prevent unauthorized personnel from misoperating or touching.

Reasonable layout: According to the frequency of use and batch management of pigments, the storage area is reasonably arranged to ensure easy access. Commonly used pigments are placed in easy-to-access locations.