How do scintillance pearlescent pigments compare to other pearlescent pigments?

The main differences between scintillance pearlescent pigments and other pearlescent pigments are the visual effects and application characteristics they present. Here are some possible differences:

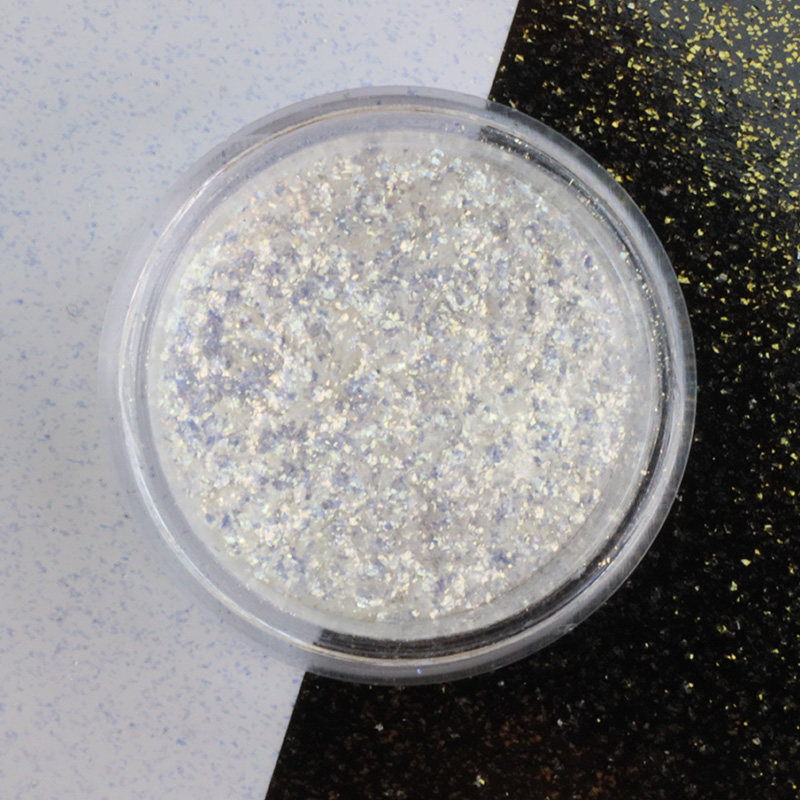

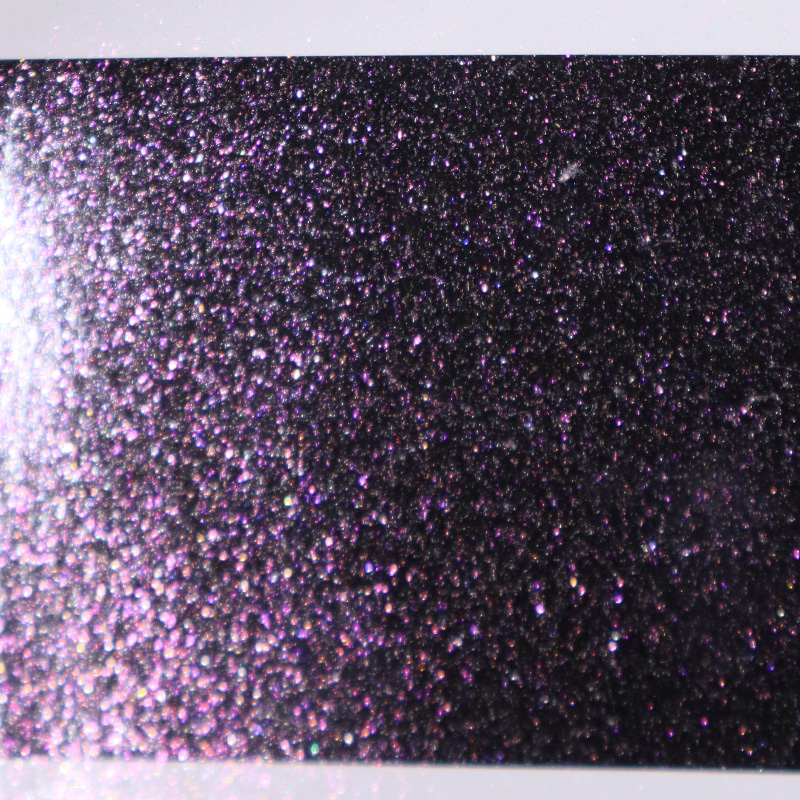

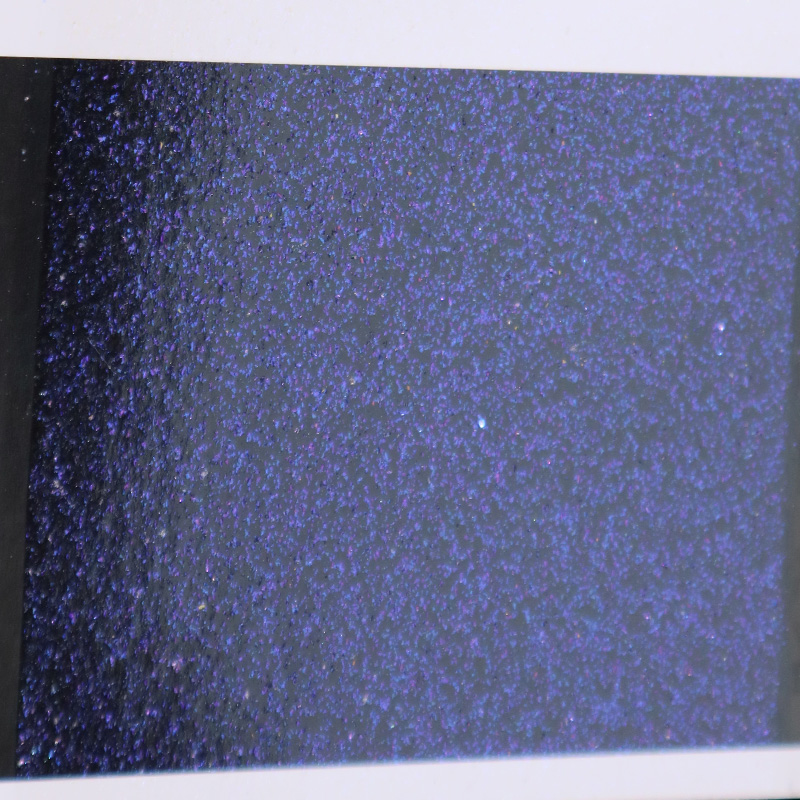

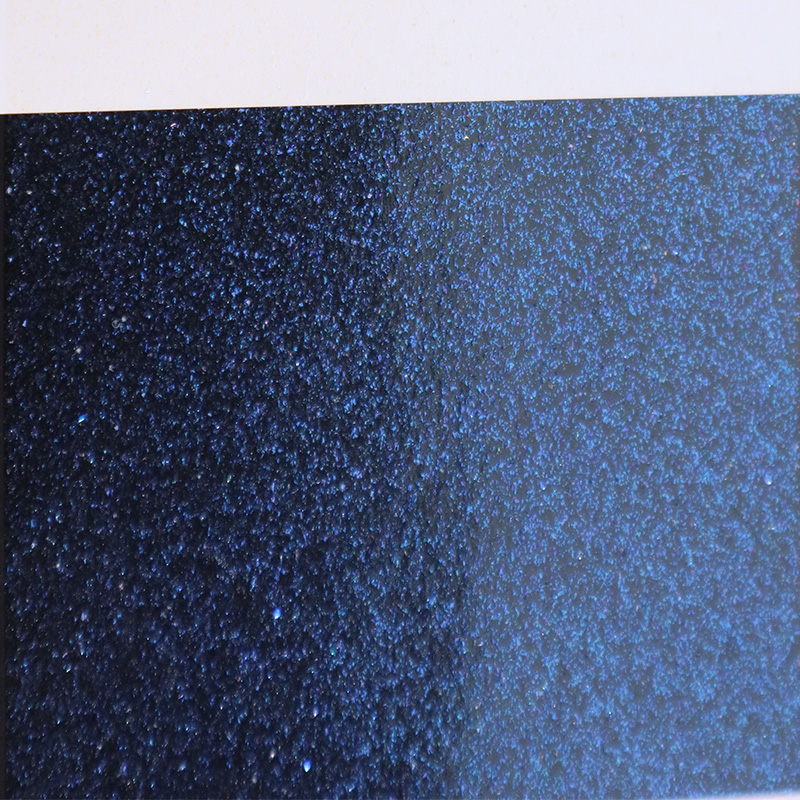

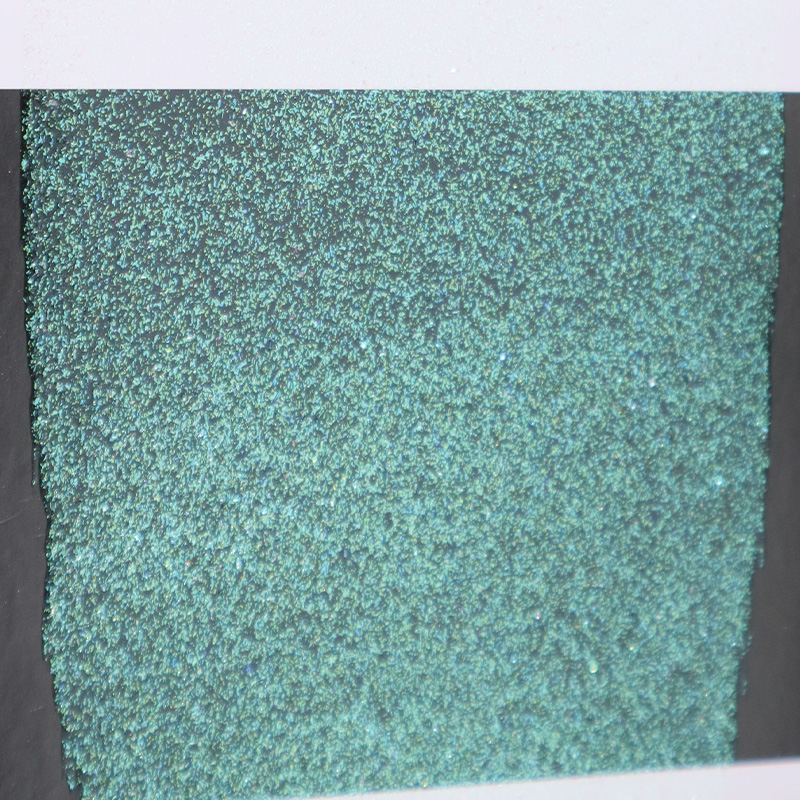

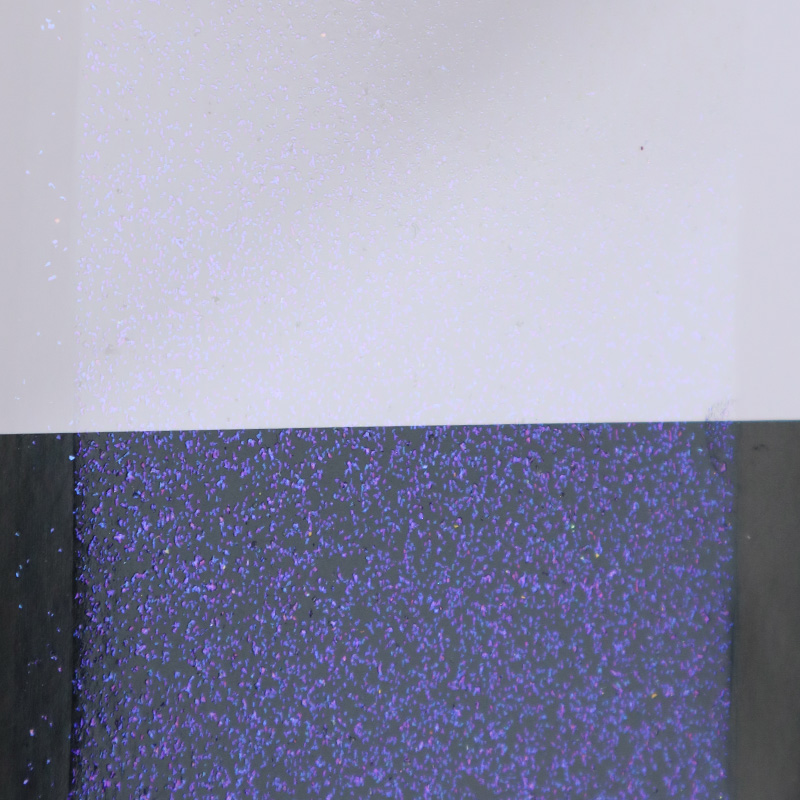

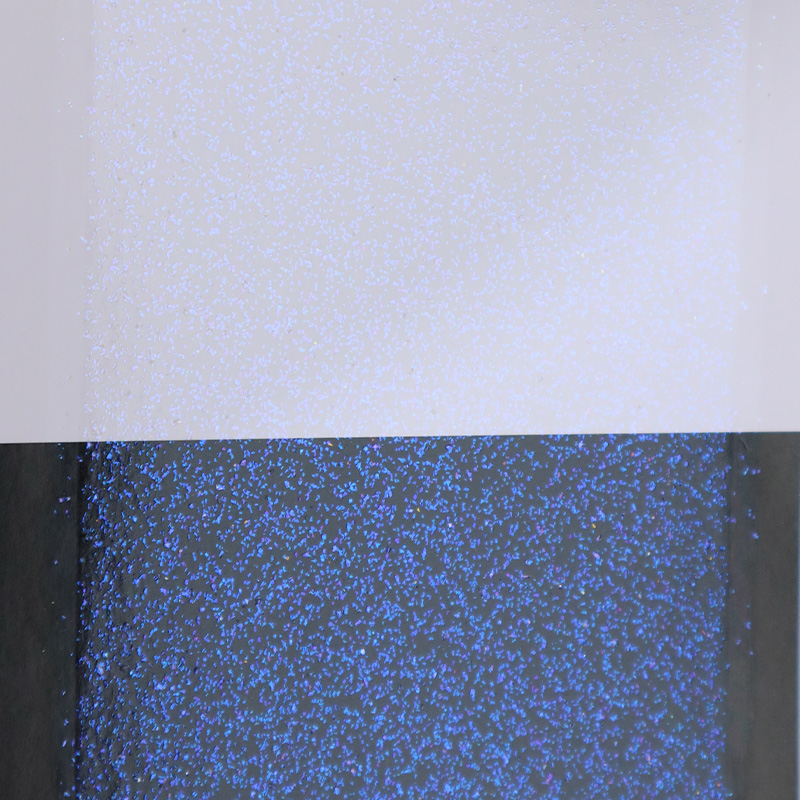

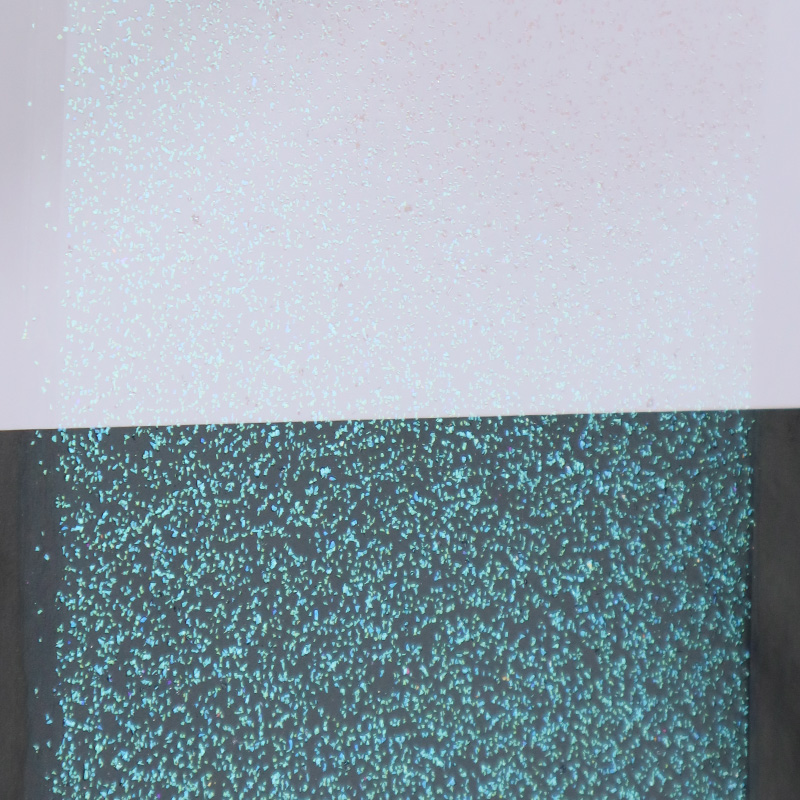

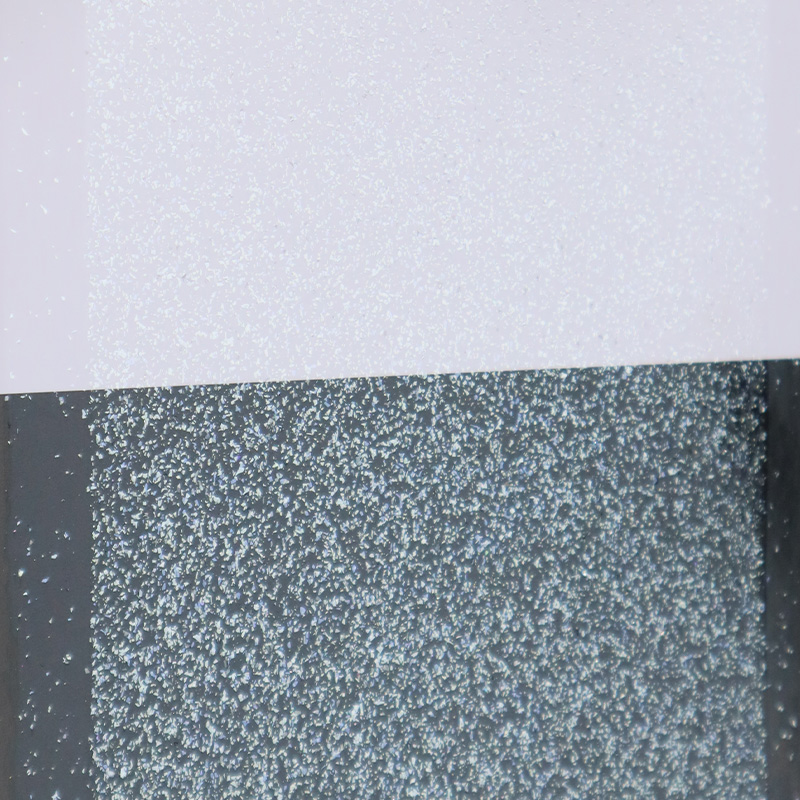

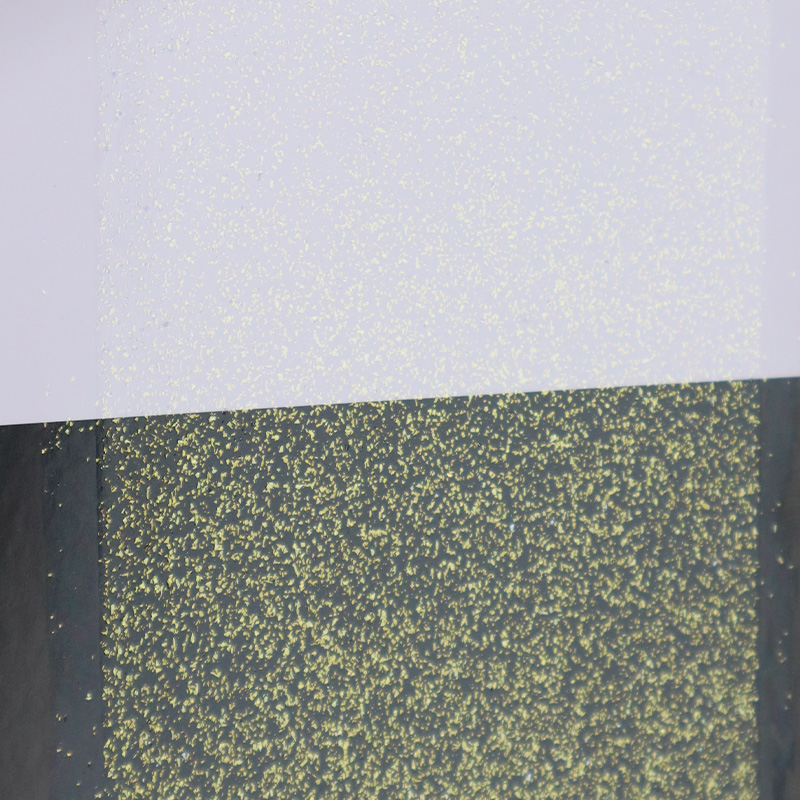

Scintillance pearlescent pigments usually have a stronger luster effect and can produce a noticeable sense of sparkle when exposed to light.

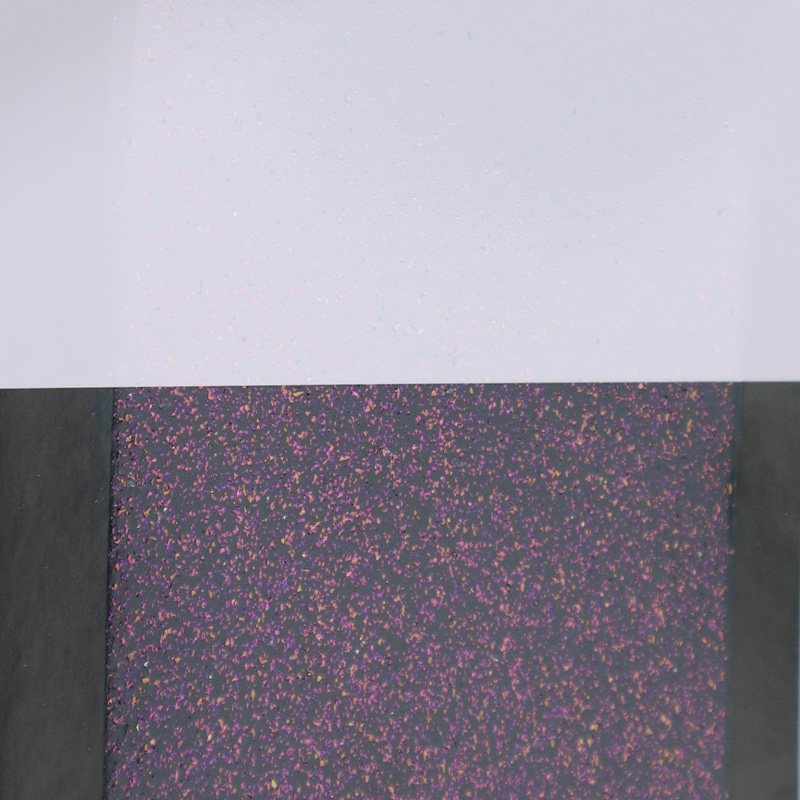

Scintillance pearlescent pigments have richer and more obvious color changes under different angles of light, while other pearlescent pigments may have a more uniform color change.

Scintillance pearlescent pigments may have different particle sizes than other pearlescent pigments, which affects their luster and sparkle effect.

Scintillance pearlescent pigments may have thicker coatings to enhance reflection and refraction, while other pearlescent pigments may have thinner coatings.

Scintillance pearlescent pigments may use special metal oxide coatings to produce unique color and luster effects.

The dispersion of scintillance pearlescent pigments in the substrate may be specially optimized to ensure uniform distribution and best effect.

Scintillance pearlescent pigments may be more suitable for applications that require strong visual impact and special effects, while other pearlescent pigments may be more suitable for daily or commercial use.

Sparkling pearlescent pigments may cost more than other pearlescent pigments due to differences in production processes and materials.

Sparkling pearlescent pigments may have better weather and chemical resistance, allowing them to maintain their effects in a variety of environments.

Sparkling pearlescent pigments may use more environmentally friendly materials and production processes to reduce the impact on the environment.

What are the differences in coating thickness for scintillance pearlescent pigments compared to other pearlescent pigments?

There may be some differences in coating thickness for scintillance pearlescent pigments compared to other pearlescent pigments, which can affect the pigment's gloss, glitter effect, color performance, and performance in the final application. Here are some possible differences and related factors:

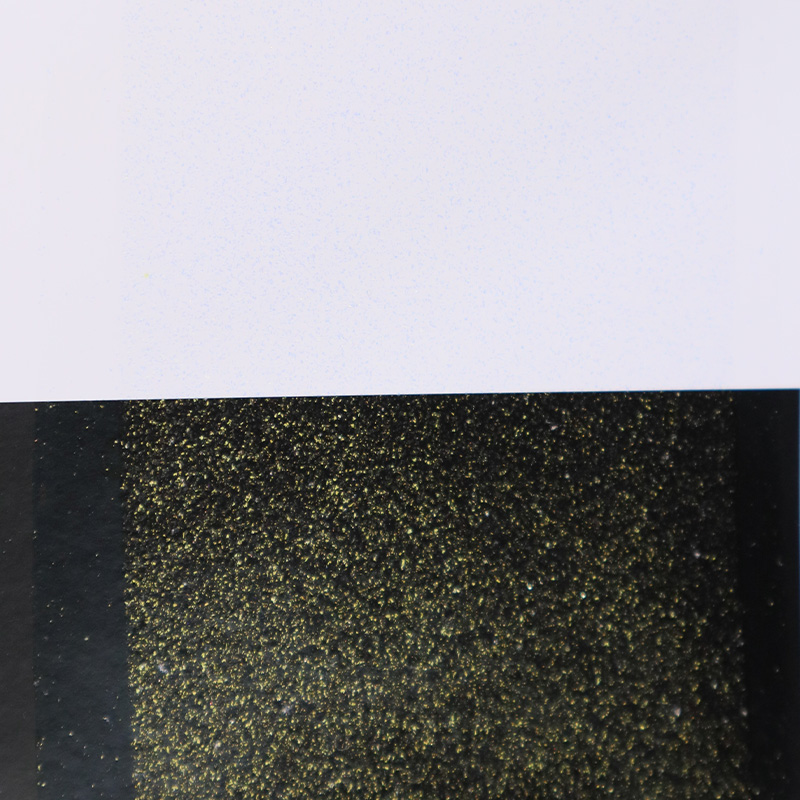

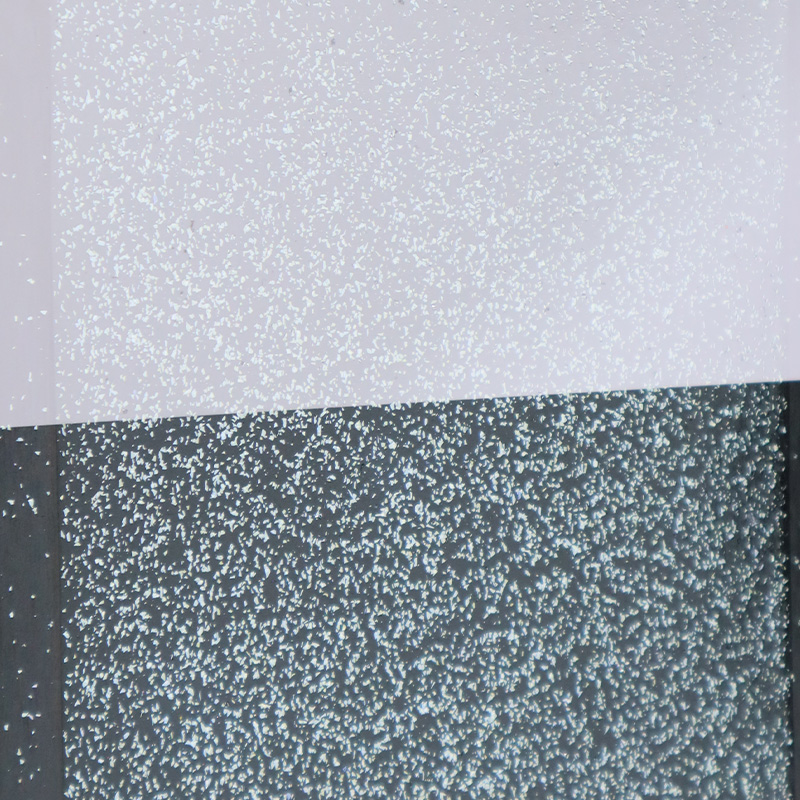

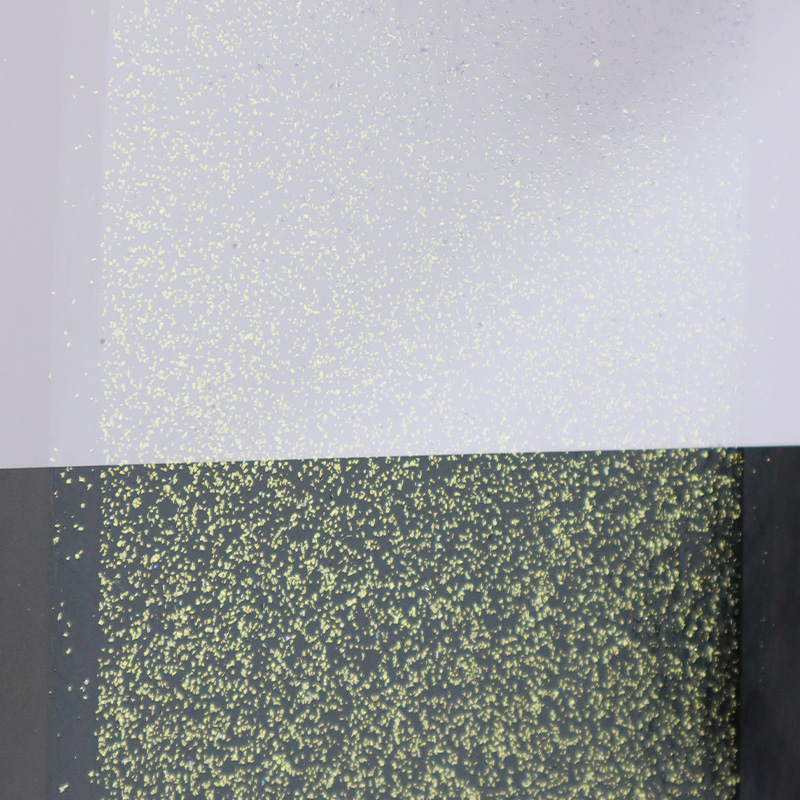

Scintillance pearlescent pigments typically have thicker coatings, which helps to enhance the reflection and refraction of light, resulting in a more intense gloss and glitter effect. Other pearlescent pigments may have thinner coatings, which may have relatively weak gloss and reflective effects, suitable for applications that require a softer sheen.

Increased coating thickness for scintillance pearlescent pigments can enhance the saturation and depth of color, making the color variations richer and more dynamic. Thinner coatings of other pearlescent pigments may provide a more natural or softer color effect, suitable for applications that do not require a strong color impact.

The thickness of the scintillance pearlescent pigment coating directly affects the intensity of the glitter effect. Thicker coatings can produce more noticeable glitter and sparkle effects, especially when the light changes or the viewing angle changes. Thinner coatings of other pearlescent pigments may produce a more subtle glitter effect, or almost no glitter effect, suitable for applications that require a more low-key gloss.

Thicker coatings of glittering pearlescent pigments may provide better durability because the thickness of the coating can protect the pigment particles and reduce wear. Thinner coatings of other pearlescent pigments may be slightly less durable, especially in high-wear environments.

Due to the thicker coating, glittering pearlescent pigments may require special formulations and processes to ensure uniform dispersion and stability of the pigment in the application. Thinner coatings of other pearlescent pigments may be easier to mix and disperse with other materials and suitable for a wider range of applications.

Thicker coatings of glittering pearlescent pigments may increase production costs because more raw materials and potentially more complex coating processes are required. Thinner coatings of other pearlescent pigments may help reduce costs because less raw materials are used.

If the coating material is environmentally friendly, then the environmental friendliness of glittering pearlescent pigments can be maintained even with thicker coatings. Other pearlescent pigments Similarly, the environmental friendliness of the coating depends on the materials and production process used.

The coating thickness of glittering pearlescent pigments can be adjusted according to customer needs to achieve specific gloss and glitter effects. Other pearlescent pigments can also adjust the coating thickness according to application needs to meet different visual effects and performance requirements.

The increased thickness of the coating of glittering pearlescent pigments may bring technical challenges, such as coating uniformity, adhesion and shrinkage during baking. Other pearlescent pigments Thinner coatings may be easier to control technically, but still require precise processes to ensure the best results.

Sparkling pearlescent pigments As technology develops, the control and optimization of coating thickness may lead to new innovations, such as more environmentally friendly materials, more efficient production processes, etc. Other pearlescent pigments Similarly, technological advances may also make the adjustment of coating thickness more flexible to adapt to changing market needs.