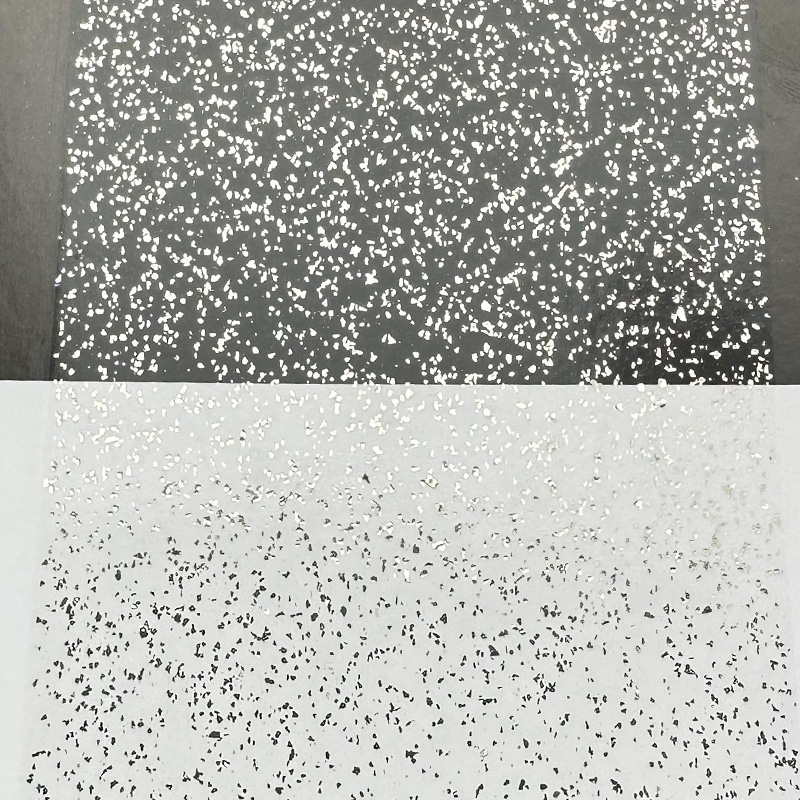

What are the effects of storing Rayshine silver-plated pearl pigment in an overly dry environment?

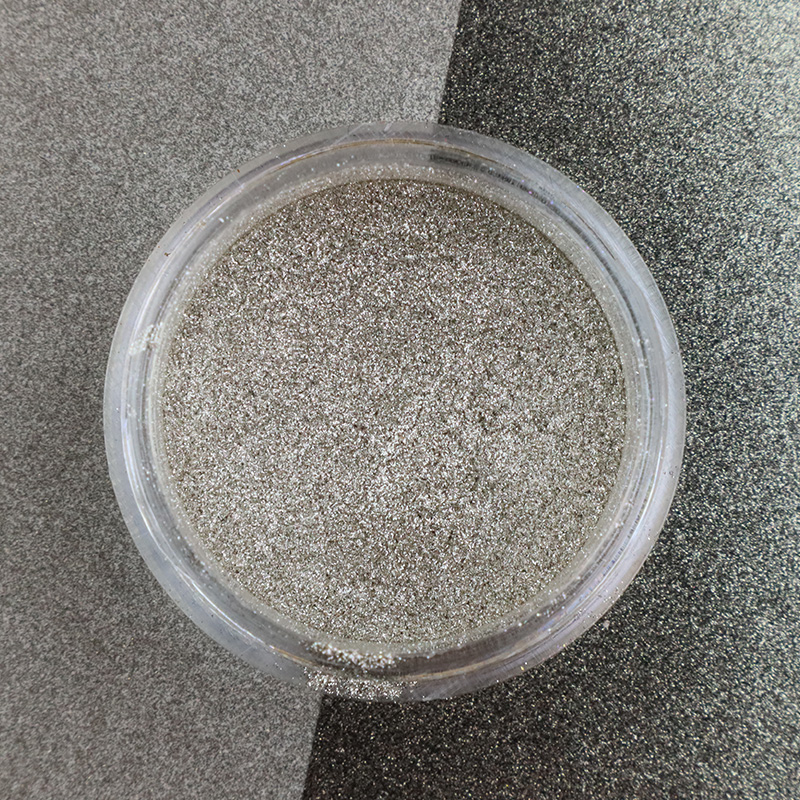

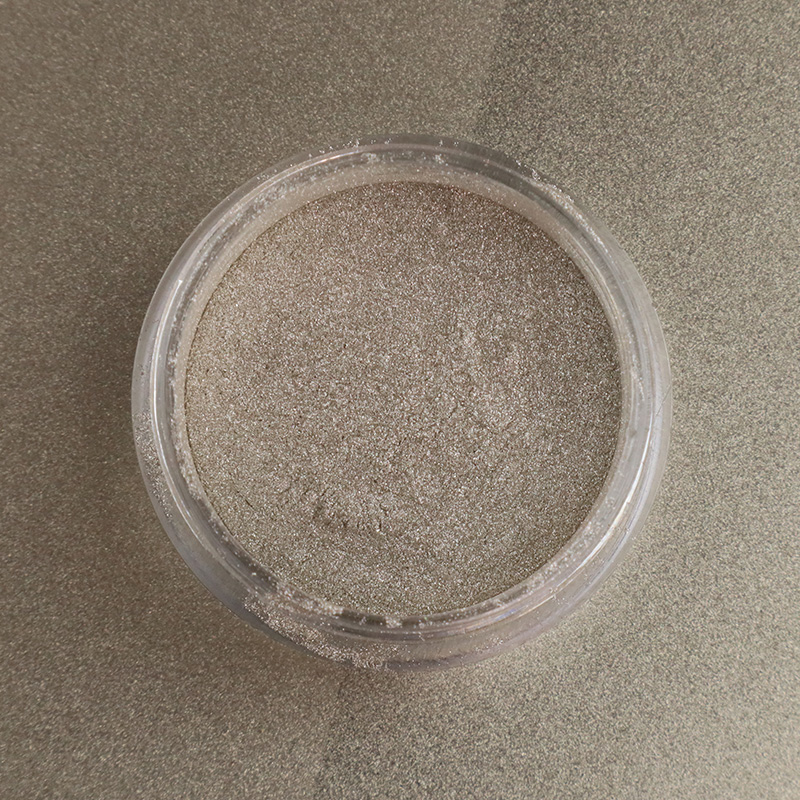

Rayshine Silver-plated pearl pigment is a special pigment used in products such as cosmetics, paints and coatings, and is highly favored for its unique luster and color effects. When storing silver-plated pearl pigment, environmental conditions have an important impact on its performance and service life. An overly dry storage environment may have a variety of adverse effects on this pigment.

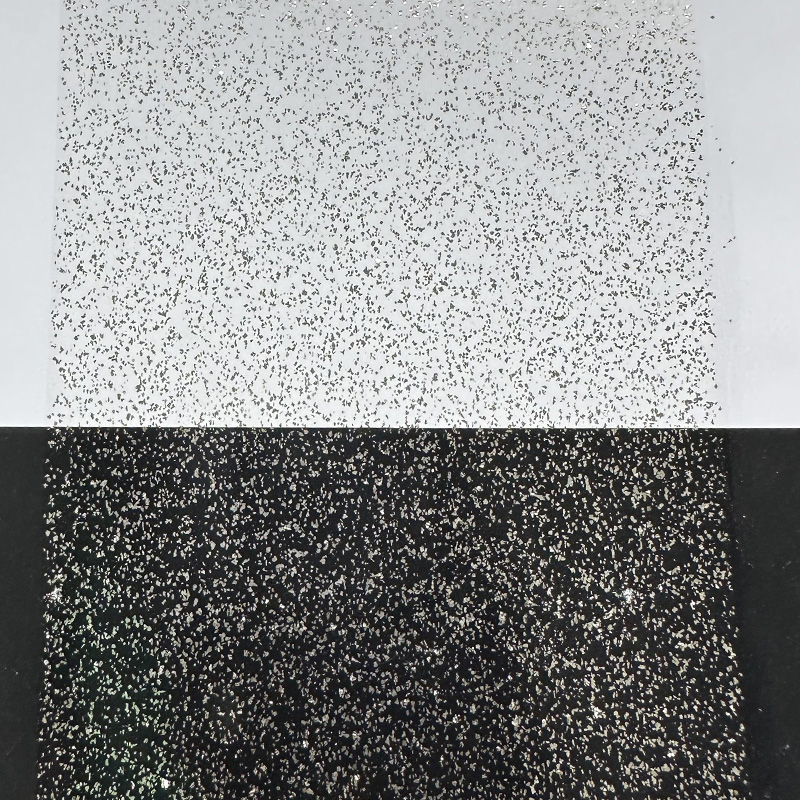

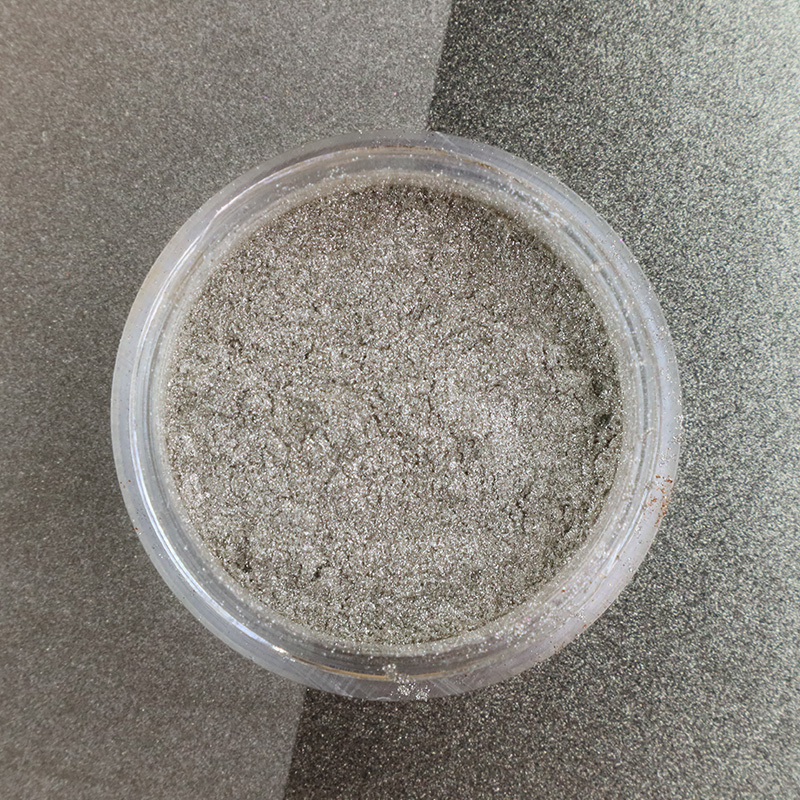

In a dry environment, the accumulation of static electricity may increase. This may cause the pigment particles to adsorb to each other, forming agglomerations that are difficult to disperse, affecting the uniformity of the pigment and the appearance quality of the final product.

Silver is a relatively active metal that easily reacts with oxygen in the air to form silver oxide (Ag2O). Although in general, the silver coating will have certain protection measures, in an overly dry environment, the surface of the silver is more susceptible to oxidation due to the lack of moisture protection. This oxidation reaction causes the silver coating to lose its luster and affects the visual effect of the pigment.

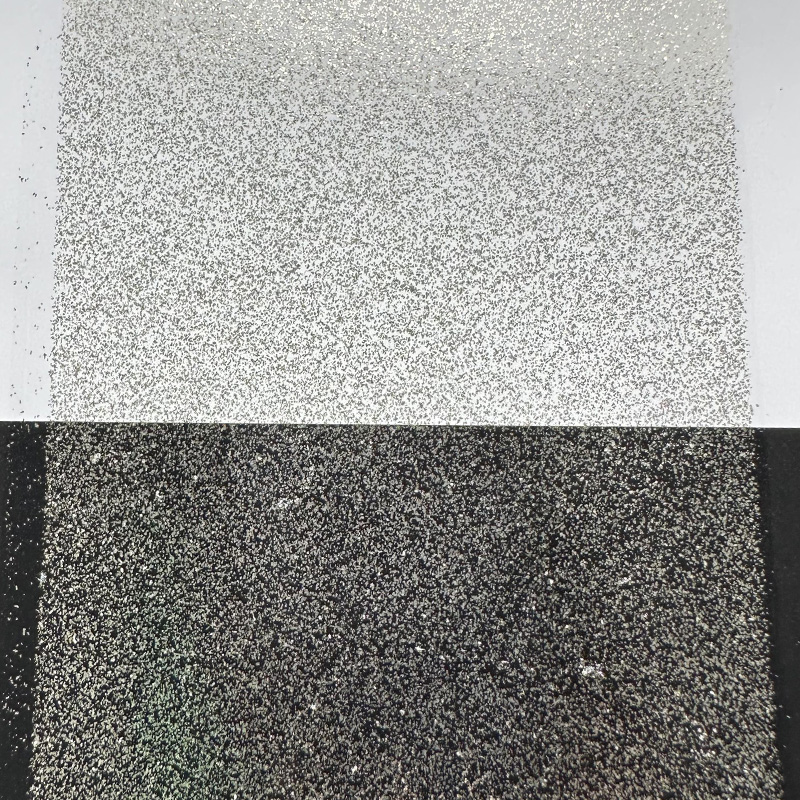

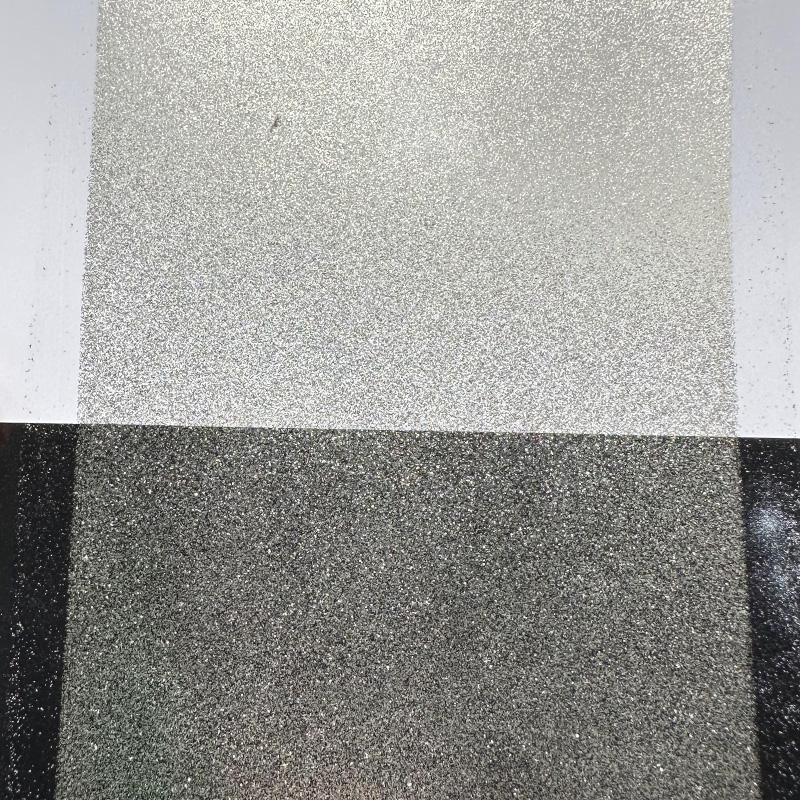

Silver-plated pearl pigments are composed of tiny particles that can maintain a certain degree of dispersion under appropriate humidity. However, in an overly dry environment, the electrostatic interaction between the particles may be enhanced, causing the particles to agglomerate. This agglomeration phenomenon will affect the uniformity of the pigment, making it difficult to achieve the desired effect during application and affecting the appearance quality of the product.

The mica substrate may lose some moisture in an extremely dry environment, resulting in a decrease in its mechanical strength and becoming brittle. This embrittlement of mica will make the pigment more easily broken during processing and use, reducing its service life and effect.

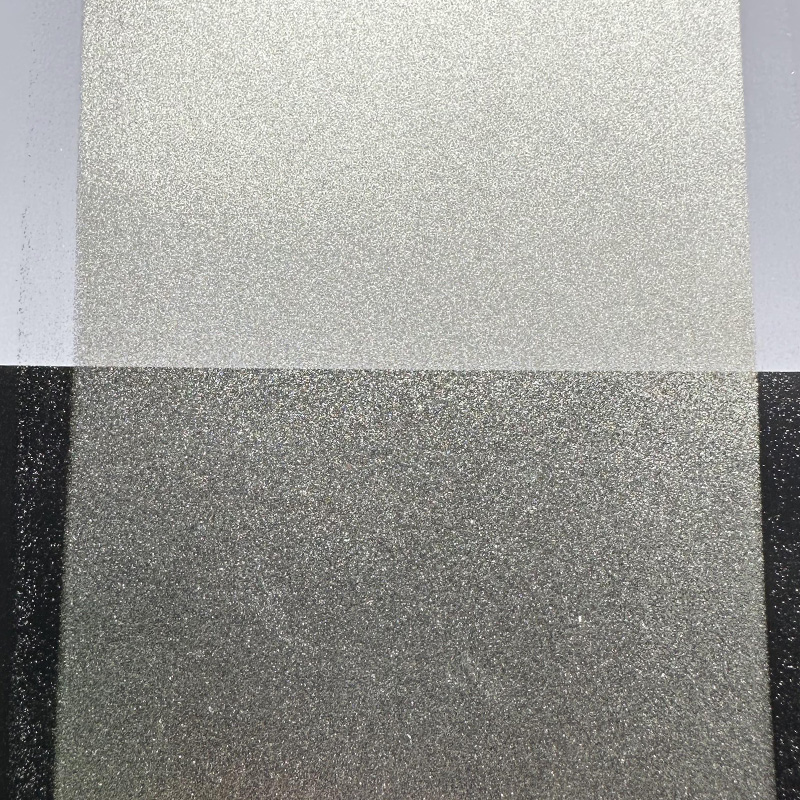

The color effect of silver-plated pearl pigment depends on the optical properties of the silver coating. In an overly dry environment, the surface oxidation and particle agglomeration of silver will affect its reflection and refraction properties, resulting in changes in color effects. This change may make the color of the pigment dull and lose its original brightness and brightness.

Due to problems such as particle agglomeration and substrate embrittlement, the performance of silver-plated pearl pigments in actual applications may be significantly reduced. For example, when used in cosmetics, problems such as uneven coloring and easy powder loss may occur; when used in coatings, it may cause uneven coating and easy peeling.

How to prevent static electricity accumulation in Rayshine Silver Coated Pearls Pigment?

Preventing static electricity accumulation in Rayshine Silver Coated Pearls Pigment is an important issue, because static electricity can cause pigment particles to aggregate, disperse unevenly, and may even cause fire or explosion. Here are some detailed measures that can help reduce or prevent static electricity accumulation:

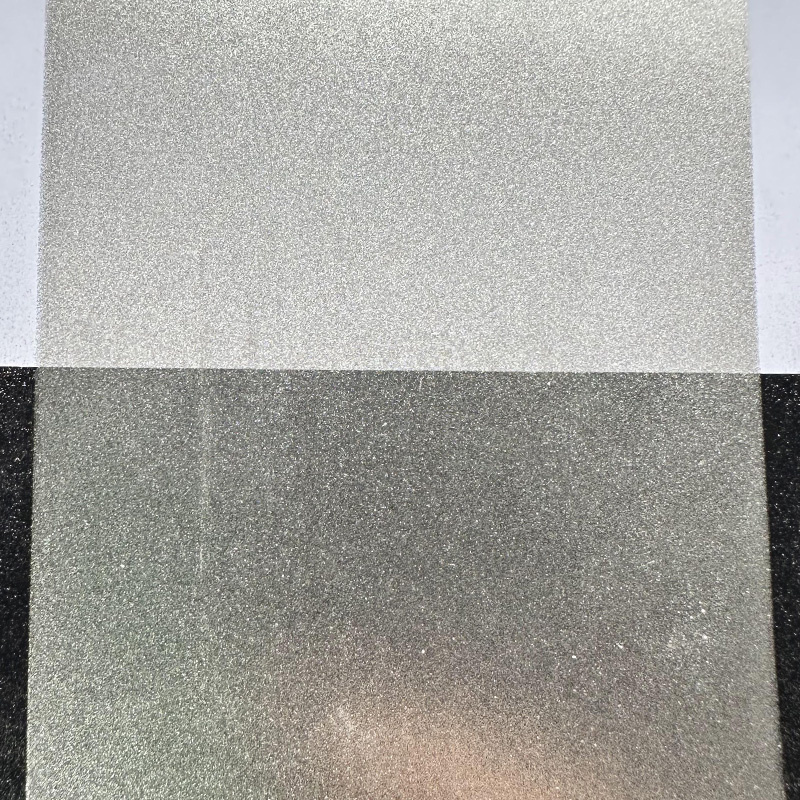

Environmental humidity is one of the key factors affecting static electricity accumulation. In a dry environment, static electricity is more likely to be generated and accumulated. Therefore, keeping the relative humidity of the environment where the pigment is stored and used between 40% and 60% can significantly reduce static electricity problems.

Adding antistatic agents, such as surfactants or specific polymers, to the pigment formulation can help reduce the generation of static electricity. These additives can improve the surface properties of pigment particles and reduce static electricity generated by friction and contact.

Ensuring that the pigment is evenly dispersed in the medium can reduce friction between particles, thereby reducing the generation of static electricity. Using appropriate dispersants and stirring techniques can improve the dispersibility of the pigment.

Choosing suitable packaging materials, such as antistatic plastic or metal containers, can reduce the generation and accumulation of static electricity. In addition, ensure the sealing of the packaging material to prevent the influence of environmental factors on the pigment.

During the storage and use of pigments, the use of grounding equipment, such as grounding mats, grounding wires, and grounding clips, can safely direct static electricity to the ground, thereby reducing the risk of static electricity accumulation.

Operators wearing anti-static clothing, such as anti-static shoes, anti-static gloves, and anti-static work clothes, can reduce the impact of static electricity generated by the human body on the pigment.

Regular cleaning and maintenance of pigment handling equipment, such as agitators, conveyor belts, and storage containers, can reduce the accumulation of static electricity. The use of anti-static cleaners and tools can further improve the cleaning effect.

During the conveying and mixing of pigments, avoid rapid flow and impact, as these operations will generate friction and static electricity. Use gentle flow and mixing techniques to reduce the generation of static electricity.

In the storage and use areas of pigments, the use of ion fans can generate charged particles to neutralize static electricity in the air, thereby reducing static electricity accumulation on pigment particles.

Regularly monitor and detect static electricity levels in the environment where pigments are stored and used, and promptly detect and solve static electricity problems. The use of static electricity detection instruments, such as static electricity voltmeters and static electricity field strength meters, can provide accurate data.