What factors affect the stain resistance of antique pearlescent pigments?

The stain resistance of antique pearlescent pigments is one of the key factors in maintaining their beauty and performance in practical applications. Stain resistance refers to the ability of the pigment to resist stains and remain clean under various environmental conditions. The following are several major factors that affect the stain resistance of antique pearlescent pigments:

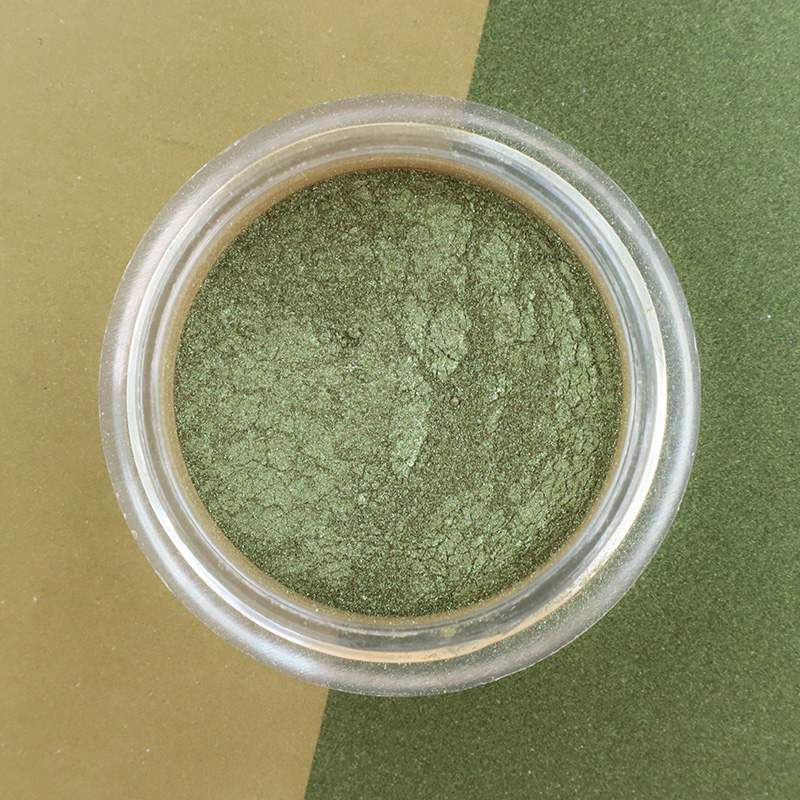

The chemical composition and formulation of the pigment are the basis for influencing stain resistance. Specific chemical additives, such as hydrophobic agents, oleophobic agents or antistatic agents, can improve the stain resistance of the pigment. These additives can reduce the adsorption of water and oil, thereby reducing the adhesion of pollutants.

Before the application of the pigment, it is crucial to properly clean and pre-treat the substrate. This includes removing grease, dust, old paint layers, etc. to ensure good adhesion between the pigment and the substrate. Good adhesion helps to form a uniform and tight coating, thereby improving stain resistance.

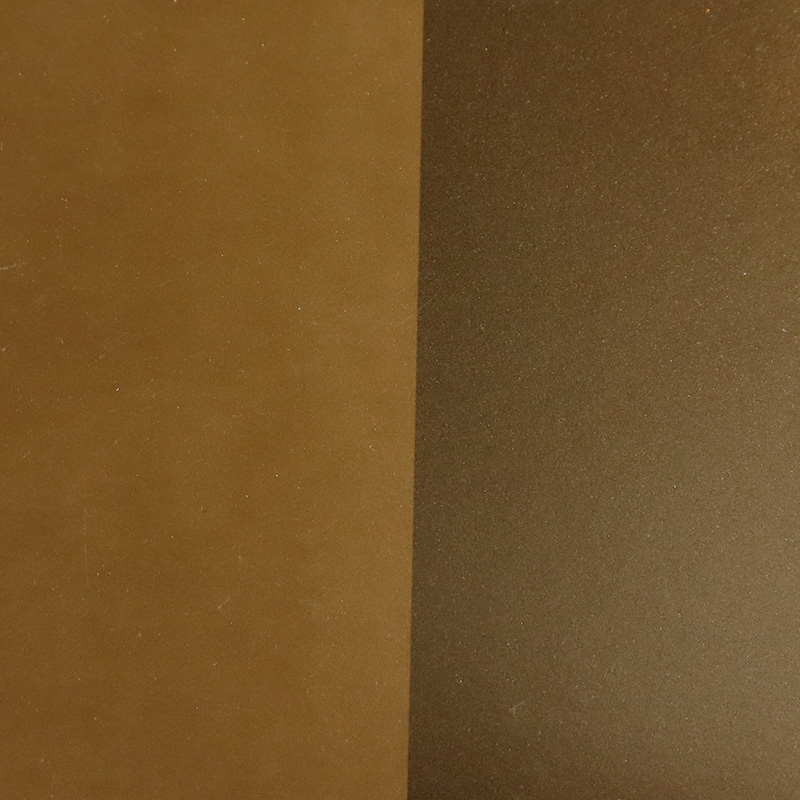

The thickness of the coating directly affects its stain resistance. Thicker coatings can provide better protection and reduce the penetration of pollutants. However, too thick a coating may also cause cracking or other problems, so it is necessary to find the right balance.

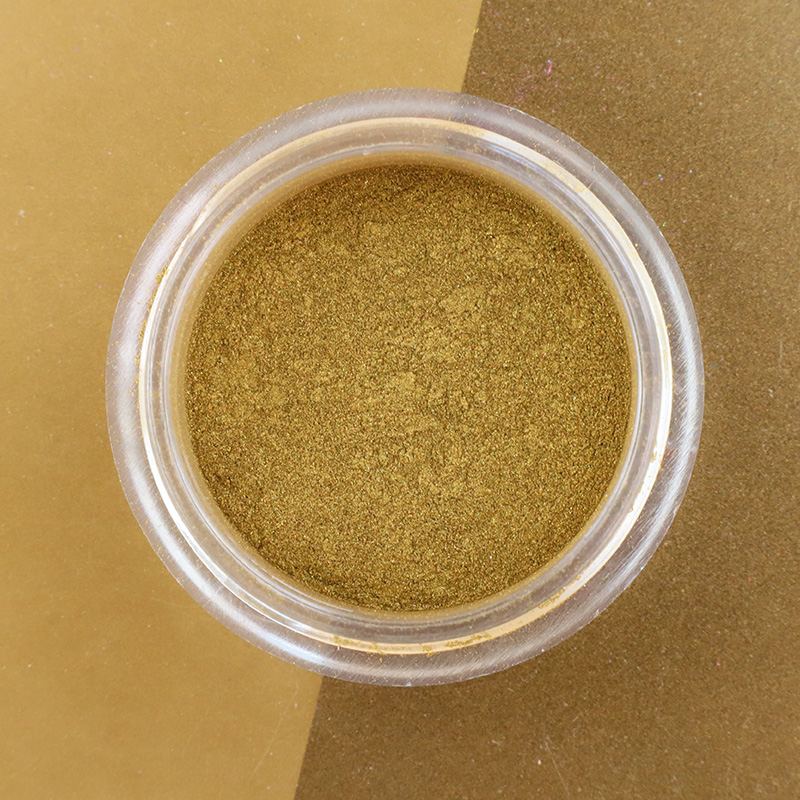

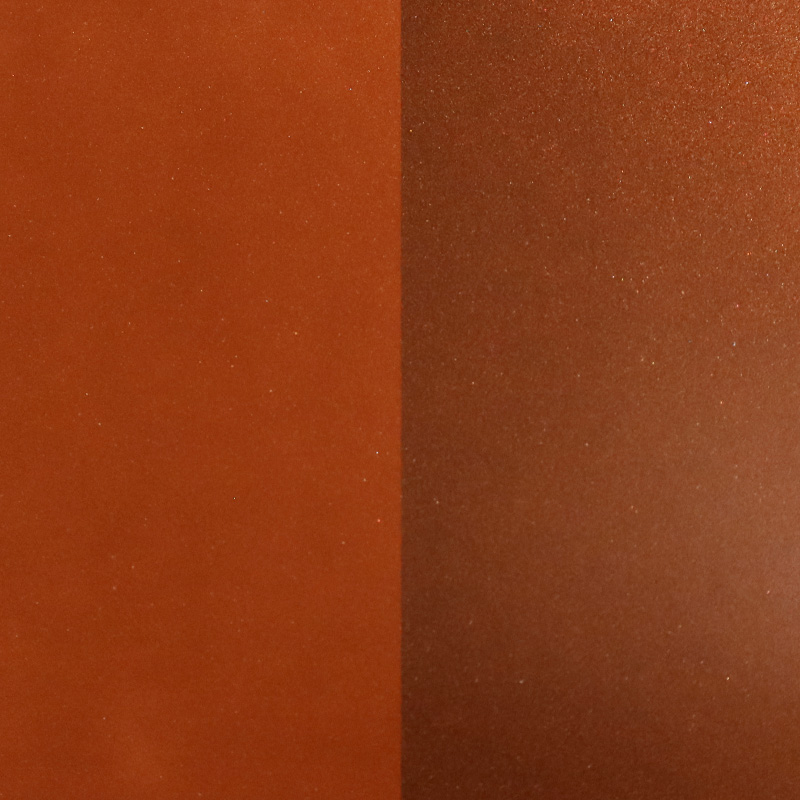

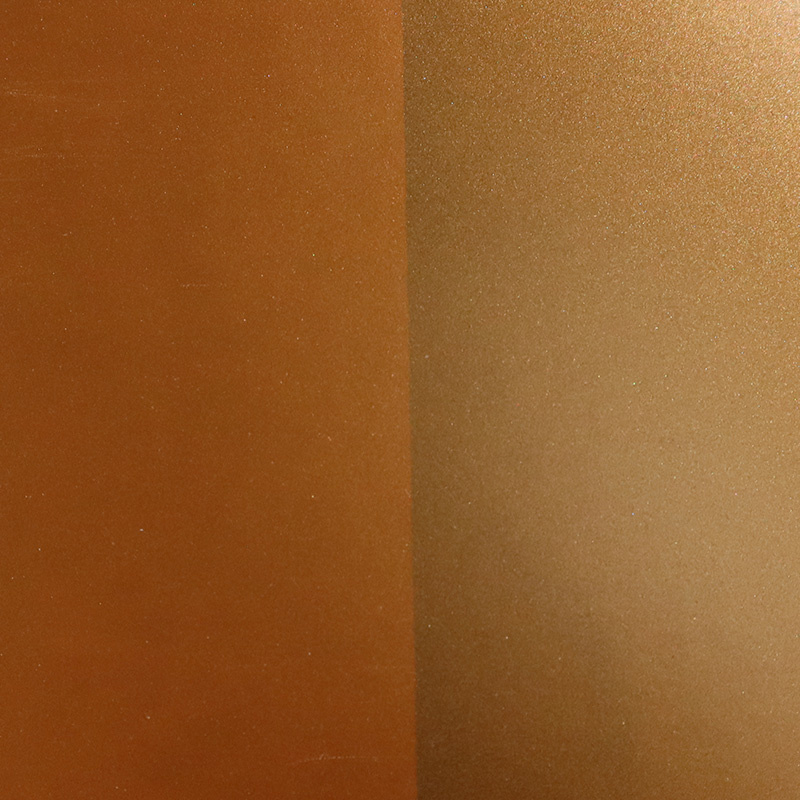

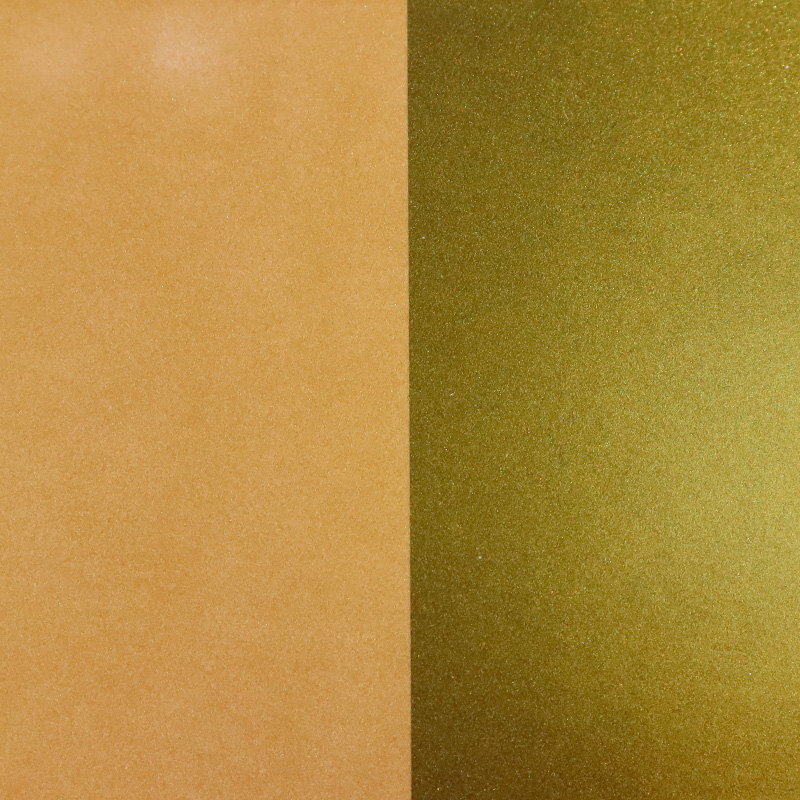

The size and shape of the pigment particles have a significant impact on the tightness and uniformity of the coating. Smaller particles help form a tighter coating, which improves stain resistance.

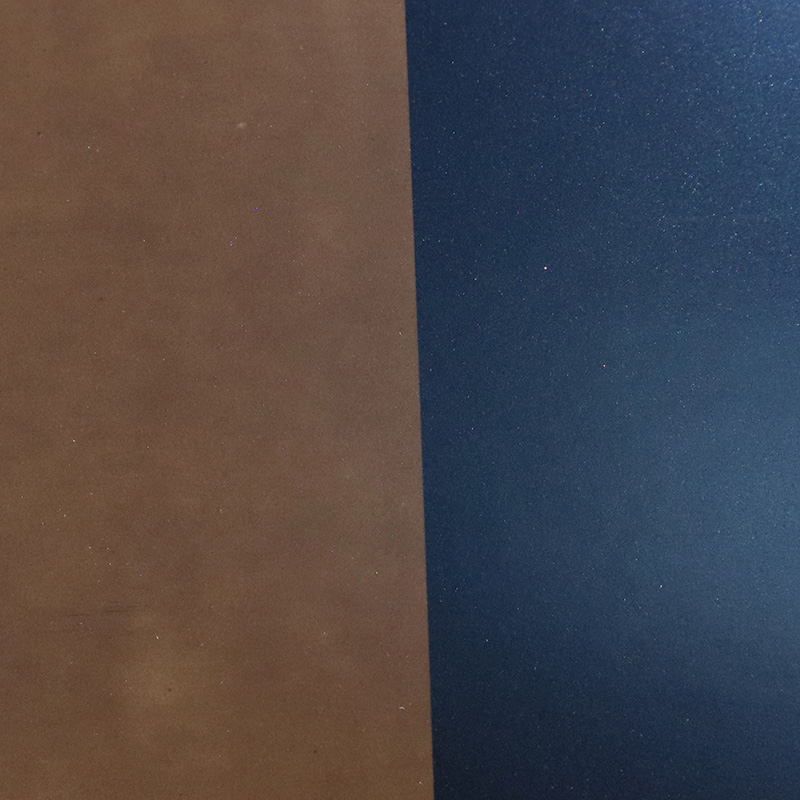

The gloss of the pigment also affects its stain resistance. High-gloss pigments can better reflect light, reduce the visibility of contaminants, and may also reduce the adhesion of contaminants due to surface tension.

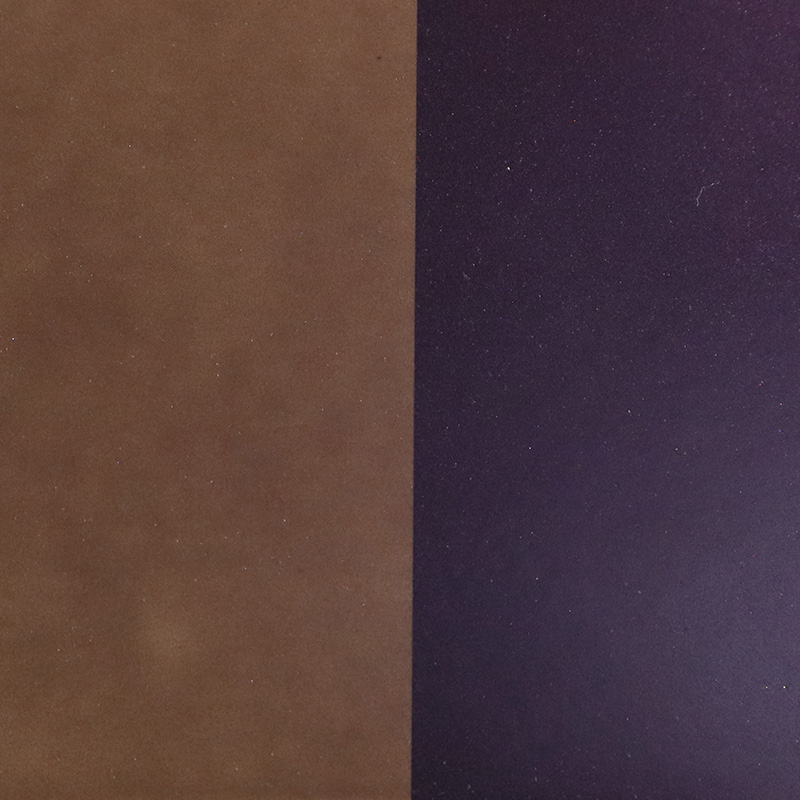

The environmental conditions in which the pigment is located, such as humidity, temperature, UV exposure, air pollutants, etc., will affect its stain resistance. For example, a high humidity environment may cause the pigment to absorb water, reducing stain resistance.

Regular maintenance and cleaning are important measures to maintain the stain resistance of the pigment. By promptly removing contaminants attached to the surface of the pigment, the penetration and accumulation of contaminants can be prevented, and the service life of the pigment can be extended.

The compatibility of the pigment with the substrate also affects stain resistance. If the bond between the pigment and the substrate is not strong, it may cause the coating to peel or crack, thereby reducing stain resistance.

The durability of the pigment refers to its ability to resist the influence of the external environment for a long time. Pigments with good durability can maintain their performance, including stain resistance, under various environmental conditions.

In a humid environment, mold may grow on the surface of the pigment, which not only affects the appearance, but also may reduce the stain resistance of the pigment. Therefore, anti-fungal performance is also an important factor affecting pollution resistance.

How to improve the stain resistance of antique pearlescent pigments? Improving the stain resistance of antique pearlescent pigments is a multifaceted process involving pigment formulation, application technology, environmental factors, and post-maintenance. Here are some specific strategies and methods: Before applying the pigment, ensure that the substrate surface is thoroughly clean and free of contaminants such as grease, dust, and old paint layers. Appropriate surface roughness can increase the contact area between the pigment and the substrate and improve adhesion. Ensure that the coating is uniform and avoid being too thick or too thin to maintain the stain resistance and overall performance of the pigment. In some cases, multiple layers of coating can provide better protection, but the compatibility and drying time between each layer need to be ensured. Choose pigment particles of appropriate size to form a tight and uniform coating. Particles of a specific shape may help improve the tightness and stain resistance of the coating. High-gloss pigments can reduce the visibility of contaminants, and may also reduce the adhesion of contaminants due to the effect of surface tension. According to the environment where the pigment is applied, choose the corresponding stain-resistant formula. During the drying and curing process of the pigment, control the temperature and humidity of the environment to ensure the best performance of the coating. Using advanced spraying techniques, such as electrostatic spraying, can improve the uniformity and adhesion of the coating. Construction in a dust-free, constant temperature and humidity environment can reduce the interference of pollutants.

Clean the pigment coating regularly to remove attached pollutants and maintain the appearance and performance of the pigment. Applying a protective layer such as varnish on the surface of the pigment coating can provide additional protection to prevent the penetration of pollutants.

Strictly inspect the raw materials of the pigment to ensure that its quality meets the requirements. Test the pollution resistance of the finished pigment to ensure that it meets the application standards.