Why are diamond interference pearlescent pigments more weather-resistant than other pearlescent pigments?

Diamond interference pearlescent pigments are more weather-resistant than other pearlescent pigments, mainly due to their unique structure and material selection. Here are some key factors:

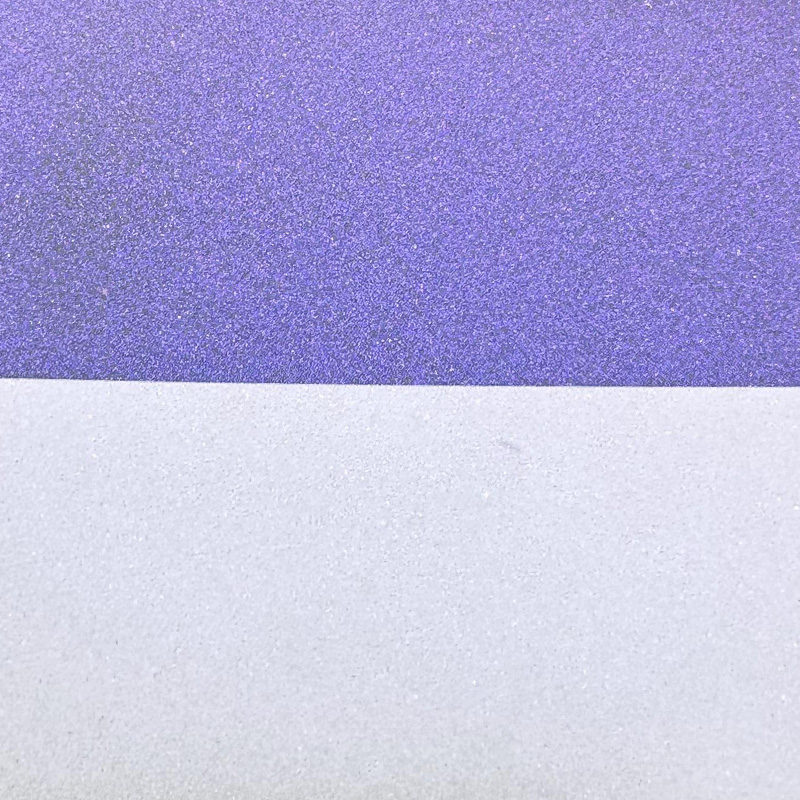

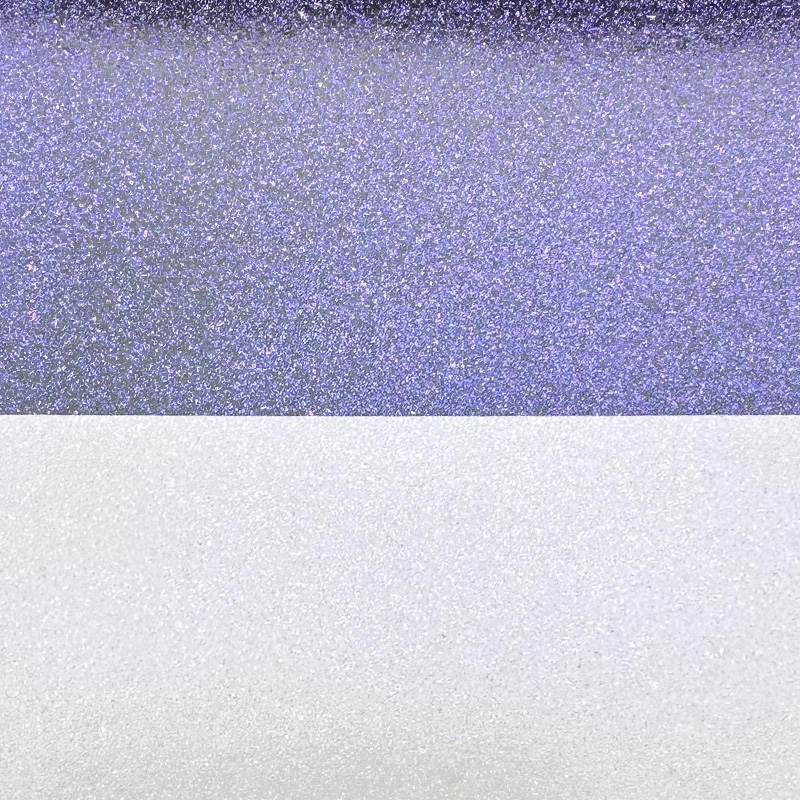

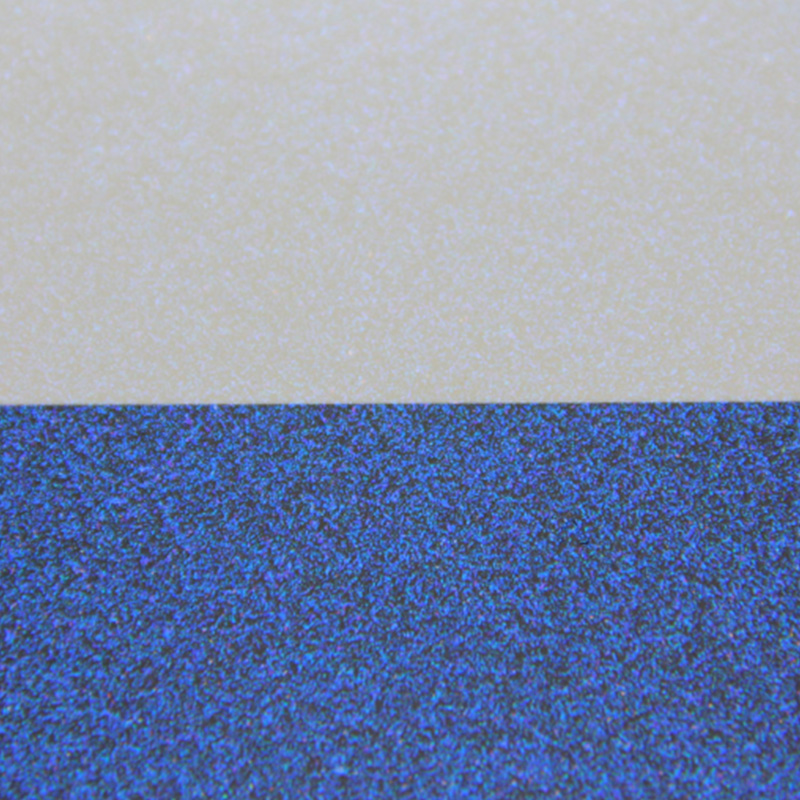

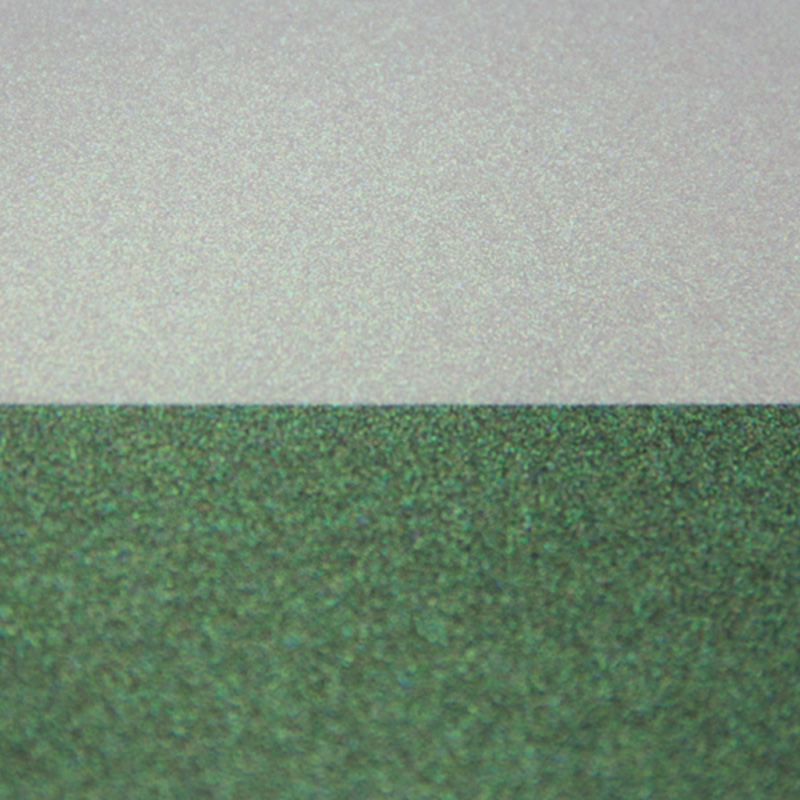

Multi-layer interference structure. Diamond interference pearlescent pigments use a multi-layer interference structure, which not only enhances the optical effect of the pigment, but also improves its resistance to environmental factors. The multi-layer structure can better disperse and reflect light, reducing direct damage to the substrate by ultraviolet (UV).

High refractive index materials. These pigments use high refractive index materials such as titanium dioxide (TiO2) and other metal oxides, which themselves have excellent weather resistance. High refractive index materials can more effectively shield ultraviolet and other harmful radiation, thereby protecting the optical properties and color stability of the pigment.

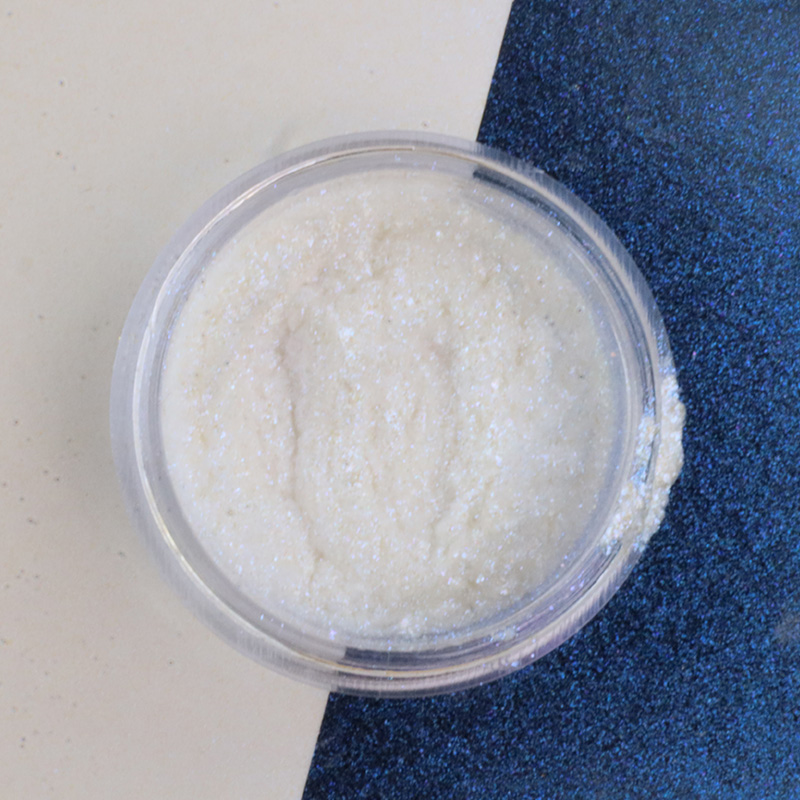

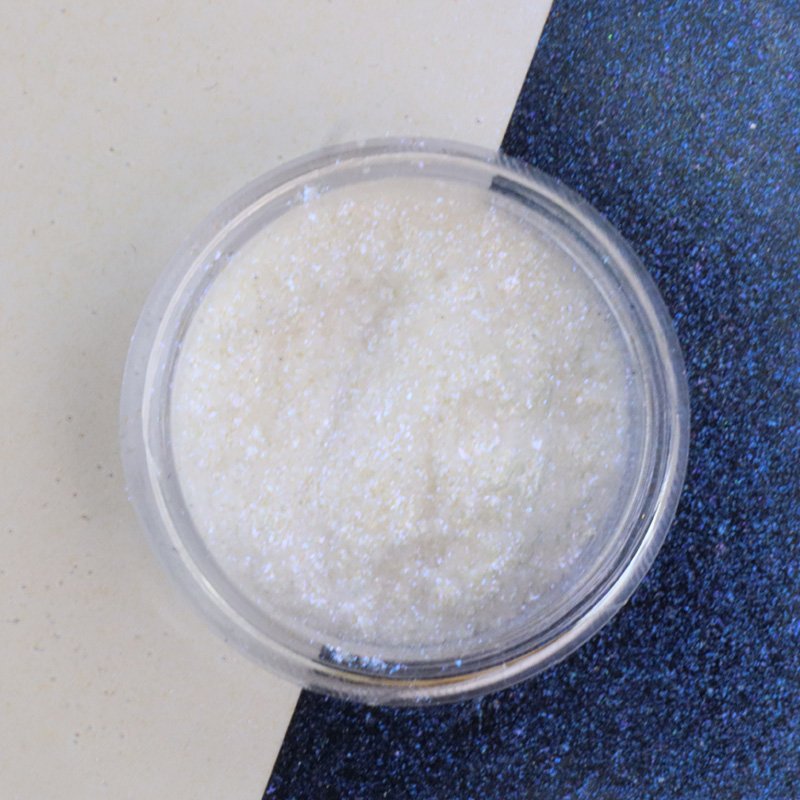

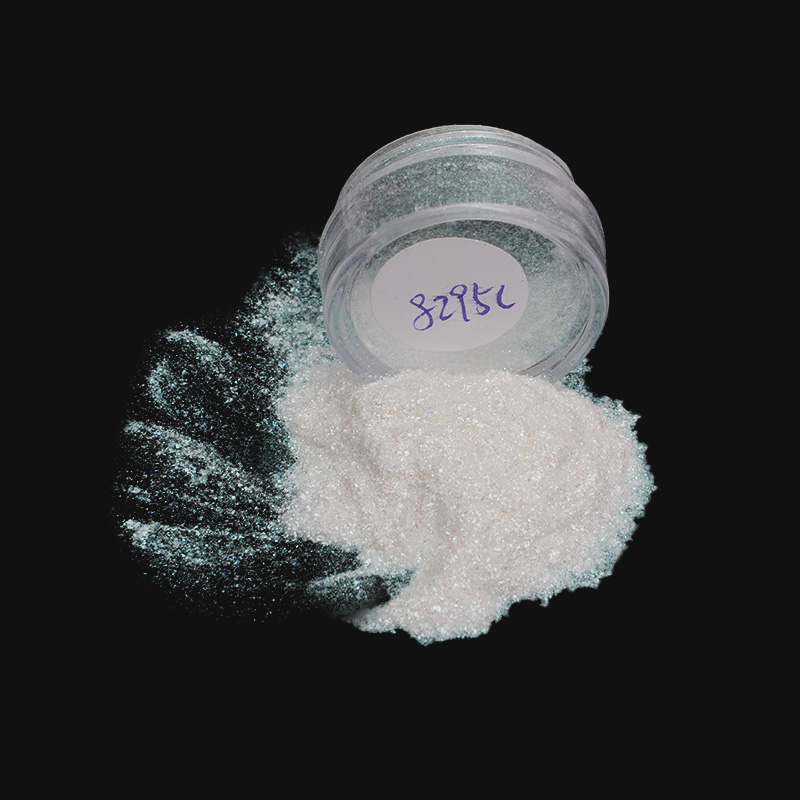

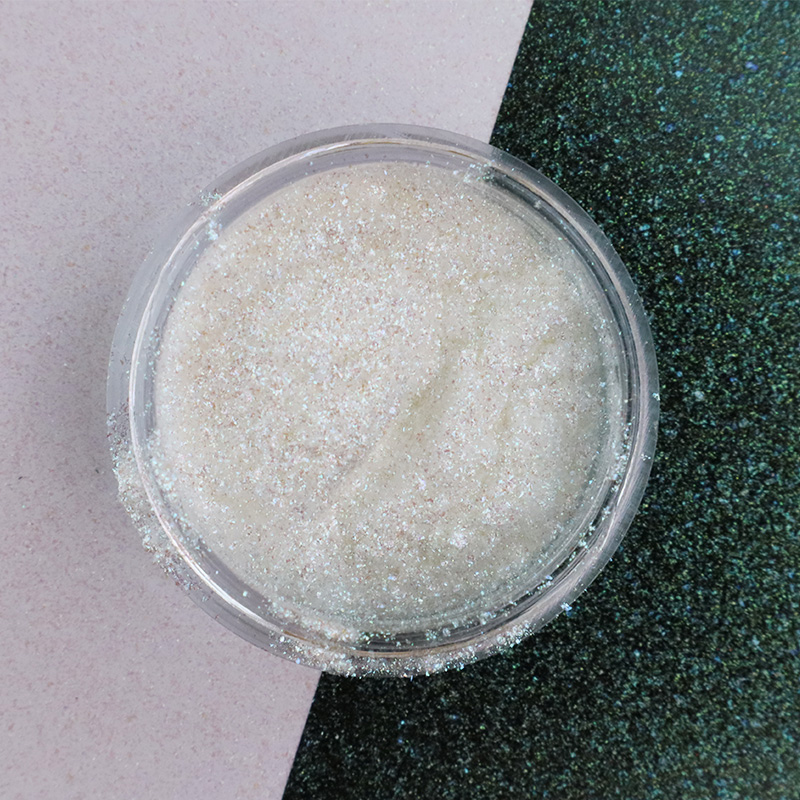

Chemical stability of materials. Diamond interference pearlescent pigments usually use materials with high chemical stability, such as synthetic mica and special coatings. These materials are not easy to react with chemicals in the environment and can maintain their stability and durability in various harsh environments.

High-quality manufacturing process. The process of manufacturing diamond interference pearlescent pigments is usually more delicate and strict, ensuring the uniform distribution and tight bonding of each layer of materials. This high-quality manufacturing process not only improves the optical effect of the pigment, but also enhances its structural stability and durability.

Anti-oxidation and anti-corrosion properties. The coating design of diamond interference pearlescent pigments usually contains antioxidant and anti-corrosion ingredients, which can effectively prevent the pigment from oxidation or degradation during long-term exposure to air, moisture and other corrosive environments. Such a coating protection mechanism significantly extends the service life and weather resistance of the pigment.

Advanced surface treatment technology. Advanced surface treatment technologies, such as surface coating and chemical passivation treatment, further enhance the weather resistance of diamond interference pearlescent pigments. Surface coating technology can form a protective layer on the surface of pigment particles to prevent moisture and oxygen from penetrating from the environment; chemical passivation treatment can reduce the chemical reaction between the pigment and the external environment.

How does the use environment affect the weather resistance of diamond interference pearlescent pigments?

The use environment has a significant impact on the weather resistance of diamond interference pearlescent pigments. Here are some of the main environmental factors and their specific impact on pigment weathering resistance:

Ultraviolet (UV) radiation. Long-term exposure to strong UV rays can cause the organic components in pigments to degrade, affecting their optical properties and color stability. UV radiation accelerates the aging and fading of pigments. Anti-UV additives are added to the pigment formula and a highly UV-resistant metal oxide coating is used to slow down the erosion of ultraviolet rays.

temperature change. Extremely high temperatures may cause thermal expansion and thermal degradation of pigments, affecting their structural stability and optical properties. Extremely low temperatures can cause the paint to become brittle, increasing the risk of it breaking and falling off. Frequent temperature changes can cause thermal stress, leading to a decrease in adhesion between pigment layers and even micro-cracks and delamination. Use substrates and coatings that are resistant to both high and low temperatures, and ensure that the pigment’s multi-layer structure is designed to withstand temperature fluctuations.

Humidity and moisture. A high-humidity environment may cause the pigment to absorb moisture and expand, affecting its physical and chemical stability, and may even cause mildew and corrosion. Moisture (especially acidic or alkaline water) can penetrate the pigment layer, causing breakdown and degradation of the pigment. Covering the surface with a waterproof protective film (such as silicone resin) and using hydrophobic coating materials can effectively prevent the intrusion of moisture.

chemical pollution. Acidic gases such as sulfur dioxide (SO2) and nitrogen oxides (NOx) can chemically react with pigments, causing them to corrode and degrade. Alkaline substances may also adversely affect the structure and color of pigments. Certain organic solvents may dissolve or damage the surface coating of the pigment, causing the pigment to lose protection. Choose materials with high chemical stability and add a protective layer on the surface of the pigment to prevent corrosion and chemical contamination.

Mechanical wear. Mechanical abrasion from sand, dust and other particles can cause surface wear and scratches on the pigment, affecting its optical effect and weather resistance. Add a wear-resistant coating to the surface of the pigment, and select a substrate with high hardness and high wear resistance.

Air Pollution. Atmospheric pollutants such as industrial smoke and automobile exhaust contain a variety of chemical components that are harmful to pigments and will accelerate the aging and degradation of pigments. Regularly maintain and clean paint surfaces to reduce the accumulation of contaminants, and use materials that are highly resistant to contamination.

The marine environment. Salt spray in the marine environment is highly corrosive and will accelerate the degradation and aging of pigments. High humidity and moist environments can also adversely affect pigments. Use materials that are resistant to salt spray and high corrosion resistance, and add a special coating that is resistant to salt spray on the surface of the paint.