Why does the visual effect of diamond gold pearlescent pigments have a uniform metallic luster?

The visual effect of diamond gold pearlescent pigments is a uniform metallic luster, which is determined by their unique material selection, structural design and optical principles. The following is a detailed explanation of this phenomenon, including material composition, structural characteristics, optical mechanism and application technology.

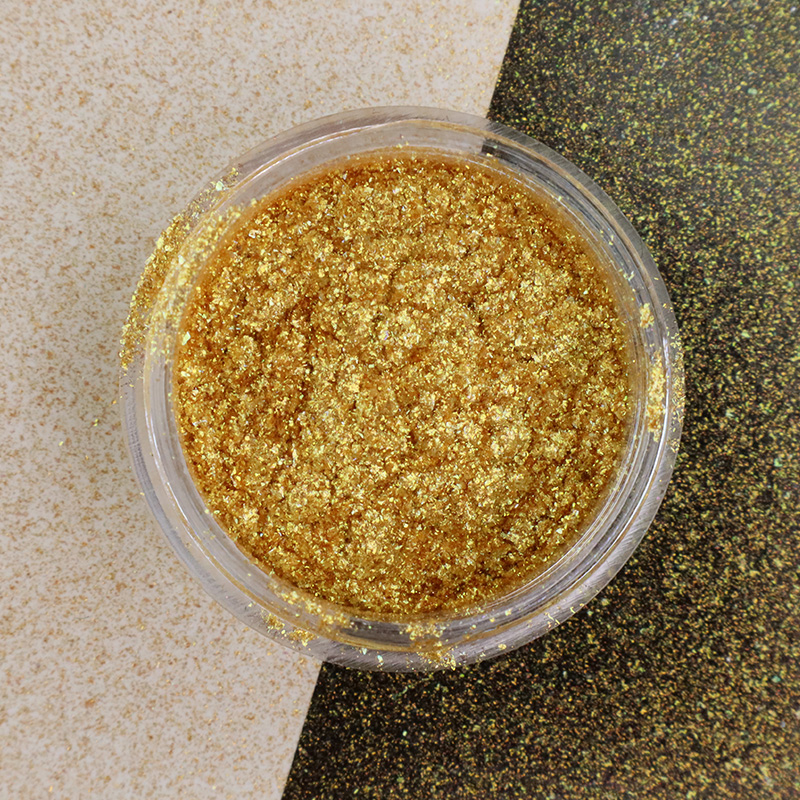

Material composition. Diamond gold pearlescent pigments usually use natural or synthetic mica flakes as the substrate. The transparency and smooth surface of mica flakes provide a good basis for the optical effect of the pigment. Titanium dioxide (TiO2) and iron oxide (Fe2O3) are common coating materials. Titanium dioxide has a high refractive index and can enhance the reflection effect of light, while iron oxide gives the pigment a golden hue.

Structural design. The structural design of diamond gold pearlescent pigments is the key to achieving their uniform metallic luster. These pigments usually adopt a layered structure, that is, one or more layers of metal oxides are evenly coated on the mica flakes. The thickness of each layer is precisely controlled to achieve the best light reflection effect. The surface of mica flakes and coating materials is very smooth, which can reflect light to the greatest extent, thus producing a metallic luster.

Optical mechanism. When light hits the surface of the pigment, part of the light is reflected, and part of the light enters the pigment and refracts and reflects multiple times. This multiple reflection and refraction enhances the brightness and gloss of the pigment. Although the interference effect of diamond gold pearlescent pigment is not as significant as that of interference pearlescent pigment, due to its multi-layer coating design, the interference of light between different layers still plays a certain role. This interference effect can keep the pigment uniform at different angles. The golden color of iron oxide combined with the high reflectivity of titanium dioxide gives the pigment a uniform golden metallic luster. By controlling the thickness and material ratio of each layer, the color and gloss effect of the pigment can be precisely adjusted.

Application technology. In practical applications, in order to ensure the uniformity and gloss effect of the coating, the pigment must be fully dispersed in the coating or medium. High-quality dispersants and mixing equipment can ensure that the pigment particles are evenly distributed and avoid agglomeration. In coating applications, uniform coating process is an important link to ensure the pigment effect. Spraying, brushing, rolling and other processes need to be precisely controlled to ensure that the pigment forms a uniform coating on the surface of the substrate. The curing and drying process of the coating will also affect the final gloss of the pigment. Uniform curing and drying can avoid surface defects and maintain the metallic gloss effect of the pigment.

Application scenarios. Diamond gold pearlescent pigments are widely used in many fields. High-end automotive coatings need to have a uniform metallic luster to enhance the appearance quality of the vehicle. The application of diamond gold pearlescent pigments can make the surface of the car present a high-brightness, high-quality metallic effect. In architectural decoration and interior design, the uniform metallic luster can enhance the visual effect and increase the luxury and modern sense of decoration. In cosmetics such as eye shadow and nail polish, diamond gold pearlescent pigments can provide a shiny metallic luster and enhance the attractiveness of the product. High-quality printed products such as business cards and packaging boxes can increase the visual impact and enhance the brand image by using diamond gold pearlescent pigments.

What factors affect the visual effect of diamond gold pearlescent pigments?

The visual effect of diamond gold pearlescent pigments is affected by many factors, which mainly involve material composition, manufacturing process, application method and environmental conditions. The following is a detailed analysis of the impact of these factors on the visual effect of diamond gold pearlescent pigments.

Manufacturing process. Coating thickness is crucial to the optical properties of the pigment. A uniform and appropriately thick coating ensures optimal light reflection and color effects. If the coating is too thick or uneven, it will result in inconsistent colors and reduced gloss. Multi-layer coating design helps to enhance interference effects and gloss. The thickness and arrangement of each layer need to be precisely controlled to ensure optimal light reflection and interference effects.

Application method. The dispersion of the pigment in the paint or medium directly affects the uniformity of the coating and the final effect. The pigment particles must be evenly distributed to avoid agglomeration to ensure a smooth and uniform gloss surface. During the spraying process, parameters such as nozzle pressure, spraying distance and angle need to be precisely controlled to ensure uniform coating. These manual methods are prone to produce brush marks and roller marks, affecting the flatness and gloss of the coating. The coating thickness needs to be consistent during the coating process, otherwise it will cause uneven gloss and color difference.

Environmental conditions. High humidity may cause the coating to absorb moisture and swell, affecting gloss and color stability. Extreme temperatures (high or low) may cause thermal expansion or contraction of the coating, affecting the stability and optical effect of the pigment. Long-term exposure to strong ultraviolet light will accelerate the aging and fading of the pigment. The organic components in the pigment may degrade, affecting the color and gloss.

Substrate surface treatment. The flatness and cleanliness of the substrate surface are critical to the adhesion and optical effect of the coating. If the substrate surface is rough or has contaminants, it will cause uneven coating and reduced gloss. The color and quality of the primer will affect the final visual effect. The right primer color can enhance the gloss and color saturation of the pigment, while high-quality primers can provide good adhesion and stability.

Curing and drying. The curing time and temperature of the coating need to be strictly controlled to ensure uniform curing and smooth surface formation. Uneven curing will cause surface defects and reduced gloss of the coating. The adhesion of dust and other contaminants needs to be avoided during the drying process of the coating to maintain the flatness and optical effect of the coating.

Chemical stability. Diamond gold pearlescent pigments may be exposed to various chemicals such as detergents, solvents, etc. during use. The chemical resistance of a pigment directly affects its long-term gloss and color stability.